General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

PCB Surface Finish: Everything You Need to Know and How to Choose

PCBA Store / 2025-06-12

Contents [hide]

What is PCB Surface Finish?

What It Means

A PCB surface finish is a thin coat put on the bare copper parts of a printed circuit board. These parts include traces, pads, ground areas, and holes. This coat acts like a shield. It stops rust, wear, and other things that can hurt how the board works or how long it lasts. PCB surface finishes use stuff like solder, natural compounds, or metal mixes. They get added in different ways, like dipping, plating with electricity, or using chemicals.

Why It’s Needed

The main job of a PCB surface finish is to keep copper traces and pads safe from rust and wear. This makes sure the board works well for a long time. The finish creates a barrier. It keeps the copper ready for soldering, which is super important when putting the board together. Also, PCB surface finishes help with things like clear signals and steady power in fast-moving tech.

Things to Think About When Picking a PCB Surface Finish

How the Board Gets Put Together

The way a board is built matters a lot for choosing a PCB surface finish. Some finishes work better with certain soldering styles, like reflow or wave soldering. You also need to think about heat settings and fixes that might be needed later.

Where It’ll Be Used

Wet Air

Lots of wet air can make copper rust faster. Some PCB surface finishes handle moisture better than others.

Hot or Cold Changes

Big swings in hot or cold can make finish materials stretch or shrink. This might cause cracks or peeling.

Harsh Chemicals

Some chemicals can eat away at certain finishes. They might lose their protective power in tough spots.

Bumps and Shakes

Shaking or hitting can mess up some finishes. Picking one that can take rough movement is key for things that move a lot.

Cost

Cost is a big deal when picking a PCB surface finish. It affects your project’s budget. Some finishes are cheap and work fine. Others cost more but last longer or work better.

How It Carries Power

Power Flow

Good power flow means signals move well with little loss.

Keeping Power Apart

Strong insulation stops short circuits or mixed signals between parts.

Steady Signals

Keeping signals steady cuts down on wobbles in fast tech.

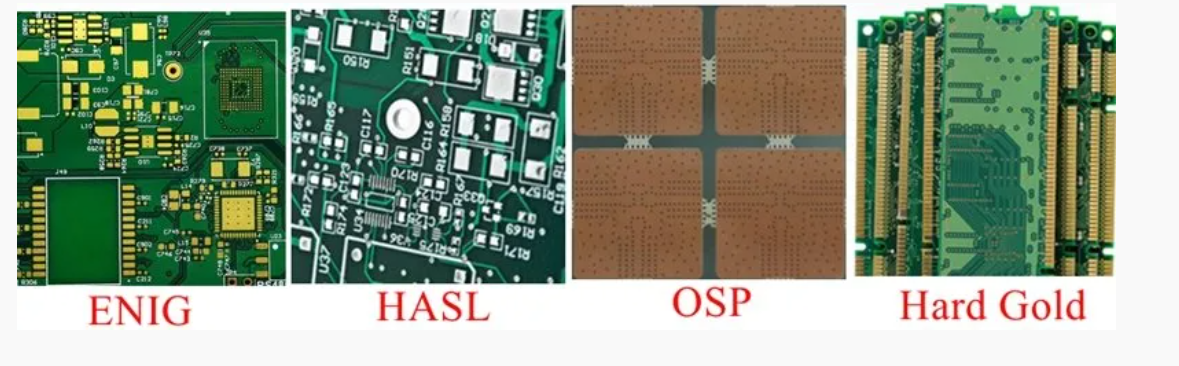

Common PCB Surface Finishes

HASL (Hot Air Solder Leveling)

HASL puts melted solder on copper pads. Then, hot air blasts off extra solder. It’s cheap but might not work for tiny parts because the surface isn’t always smooth.

ENIG (Electroless Nickel Immersion Gold)

ENIG uses a nickel layer topped with gold. It’s great for soldering and fights rust well. It lasts a long time and works with small parts.

OSP (Organic Solderability Preservatives)

OSP adds a thin natural layer to copper pads. It stops rust while keeping pads ready for soldering. It’s cheap but doesn’t last as long as other PCB surface finishes.

Immersion Tin

Immersion tin puts a smooth tin layer on copper pads using a chemical dip. It’s good for soldering but needs careful handling to stay clean.

Immersion Silver

Immersion silver gives great power flow and low resistance. It’s smooth, so it’s awesome for fast tech.

ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold)

ENEPIG mixes nickel, palladium, and gold layers. It’s super for soldering, wiring, and rust protection. It’s perfect for tricky builds that need to last.

Comparing PCB Surface Finishes

Surface Finish Comparison Chart

PCB Surface Finish | Cost | Soldering | Rust Protection | Shelf Life | Build Fit |

HASL | Low | Good | Okay | Okay | Regular builds |

ENIG | Medium | Awesome | Awesome | Long | No-lead soldering |

OSP | Low | Good | Okay | Short | No-lead soldering |

Immersion Tin | Medium | Awesome | Okay | Okay | No-lead soldering |

Immersion Silver | Medium | Awesome | Okay | Okay | No-lead soldering |

ENEPIG | High | Awesome | Awesome | Long | Mixed builds |

Smart Ways to Pick a PCB Surface Finish

Look at what your project needs, like where it’ll be used or how much it’ll get bumped. Check if it works with your build style, like no-lead soldering. Weigh cost against how well it needs to work. Think about how long it needs to stay good. Also, check how it holds up against rust based on where it’ll be.

Rules for PCB Surface Finishes

IPC Rules

IPC rules set the standards for making and building printed circuit boards. They make sure PCB surface finishes are good, steady, and reliable. Key rules include IPC-4552, IPC-4553, IPC-4554, and IPC-4556.

IPC-4552 covers ENIG PCB surface finishes. It sets the smallest thickness for nickel and gold to make sure soldering and rust protection are good. IPC-4553 is about immersion silver finishes. It talks about thickness and soldering needs. IPC-4554 guides ENEPIG finishes. IPC-4556 is for ENIPIG finishes. These rules make sure finishes work the same in all kinds of uses. Following them is a must for makers who want solid boards.

RoHS and REACH Rules

RoHS is a rule from Europe. It limits harmful stuff like lead, mercury, and cadmium in electronics. These can show up in old-school PCB surface finishes. Makers need to use no-lead options like ENIG or immersion silver to follow it.

REACH is another Europe rule. It protects people and the planet by controlling chemicals in products. PCB surface finishes must avoid banned chemicals or use safe ones to meet REACH. Following both rules keeps boards green and high-performing.

New Tech for PCB Surface Finishes

Nano-Coatings

Nano-coatings are a cool new step for PCB surface finishes. They use tiny bits to boost protection from wet air, heat, and power flow. For example, graphene-based coatings are super strong and carry power great. They’re awesome for fast tech.

Nano-silver coatings use tiny silver bits in a base. They make soldering better and fight rust stronger than regular silver finishes. Nano-coatings also make boards last longer by blocking things like wet air.

Mixed Finishes

Mixed PCB surface finishes blend different tech to get the best results. For instance, mixing ENIG with ENEPIG gives great soldering from ENEPIG and strong rust protection from ENIG. This double-layer trick makes boards super reliable for tough jobs.

Another mix uses OSP with immersion tin or silver. This boosts rust protection while keeping costs low. Mixed tech solves problems like fast signal needs or tougher builds.

Handling and Storing PCB Surface Finishes

How to Handle Them

Handling PCB surface finishes right keeps them in good shape. Always wear gloves made of clean stuff like nitrile. This stops oils or dirt from messing up the finish. Don’t touch the power-carrying parts. Hold boards by the edges or use tools like tweezers.

When stacking boards for storage or moving, use spacers to avoid scratches. Pick antistatic spacers to cut static shock risks. Work areas should have grounded mats. Workers need wrist straps tied to a shared ground.

Storing Tips

Keeping the right temperature is key for storing boards. High heat speeds up rust that hurts soldering. Keep storage at 20-25°C (68-77°F). Wet air should stay between 40-60%. Use dehumidifiers if needed.

Packing matters to stop dirt during storage. Use antistatic or moisture-proof bags with drying packs inside. Keep boards away from UV light. Store them in dark boxes or dim rooms.

Choose PCBAStore for PCB Assembly

PCBAStore gives full help for PCB assembly needs. They know tons about new tech like nano-coatings and mixed PCB surface finishes. They make sure boards work great for your project. They stick to IPC rules tightly. This promises top quality from design to finish.

By picking PCBAStore, you get awesome building skills and expert tips. They help choose the right PCB surface finish for your needs. This makes your project shine.

Extra Thoughts on Picking PCB Surface Finishes

Choosing a PCB surface finish isn’t just about one thing. It’s about matching the finish to your project’s needs, like where it’ll be or how it’s built. Each finish, like HASL, ENIG, or OSP, has its own perks. HASL is cheap but not great for tiny parts. ENIG costs more but lasts long and solders great. OSP is budget-friendly but doesn’t store well.

Think about the environment too. Wet air or harsh chemicals can hurt some finishes. Cost matters, but don’t skip on quality if your board needs to last. Following rules like IPC, RoHS, and REACH keeps things safe and green. New tech, like nano-coatings or mixed finishes, can give your board an edge, especially for fast or tough jobs.

PCBAStore’s know-how and top tools make picking and using PCB surface finishes easy. They guide you to the best choice for your board’s job, whether it’s for gadgets, cars, or medical stuff. By knowing what each finish does, you can make smart picks that keep your boards working great for years.

Previous article:A Closer Look at the PCB Plated Through-Hole Process