General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

What Is an In-Circuit Test for PCB Assemblies?

PCBA Store / 2025-05-29

Contents [hide]

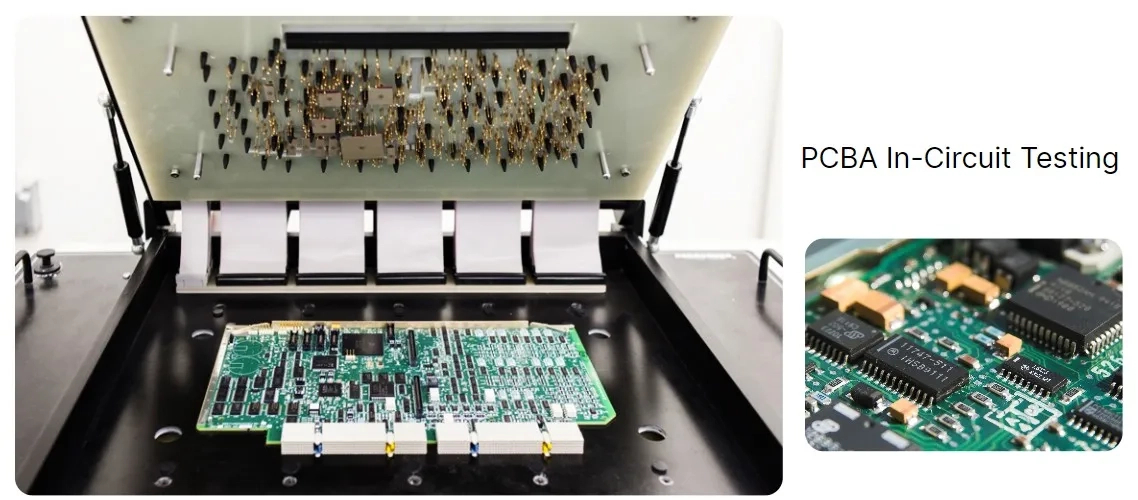

In-circuit testing, often called ICT, plays a big role in ensuring the quality of printed circuit board assemblies, or PCBAs. This testing way checks single parts on a PCB to find building mistakes before they cause trouble. By using ICT, builders achieve the best PCB assembly results, especially for tricky designs.

Understanding In-Circuit Testing for PCB Assemblies

What Is an In-Circuit Test?

An in-circuit test is an automatic method that looks at single parts on a PCB to spot building flaws. It checks part placement, electrical work, and circuit health. For example, ICT sees if resistors, capacitors, or diodes are correctly placed and working. This step is vital for advanced circuits PCB assembly, where tiny errors can lead to big failures. By catching issues like wrong parts or bad soldering, PCB in-circuit test stops faulty products from reaching buyers.

Why Is ICT Critical for PCB Assembly?

Modern PCBAs are complex, with tightly packed parts and detailed circuits. This complexity raises the chance of flaws like short circuits, open circuits, or misplaced parts. In-circuit testing PCB tackles these risks by carefully checking each part. It is very important for large-scale production, where mistakes can grow fast. The best PCB assembly service providers use ICT to ensure steady quality, lowering the chance of failures in use. As a PCB assembly service provider, using ICT helps meet buyer hopes for trusty electronics, from phones to medical tools, making it a key step in professional PCBA building.

How Does In-Circuit Testing Work?

In-circuit testing uses special tools and a clear process to check PCBAs for flaws.

Key Components of a PCBA In-Circuit Tester

A PCBA in-circuit tester is the core of ICT, built to test PCBs with accuracy. Two main tools are used: the “bed of nails” fixture and flying probe testers. The bed of nails has springy pins that touch specific test spots on the PCB, allowing electrical checks. Flying probe testers, however, use movable probes for flexible testing, great for complex boards. Software guides these tools, directing test steps and reviewing results. This setup ensures exact in-circuit testing, catching flaws like open circuits or wrong part values. These tools make ICT a dependable choice for ensuring quality in PCB assembly services China.

The ICT Process Step-by-Step

The in-circuit test process follows a clear plan to ensure thorough quality checks. First, the PCB is set up by lining it with the tester’s probes or fixture. Next, electrical signals are sent to test spots, activating parts like resistors or capacitors. The tester measures responses, such as resistance or capacitance, to find flaws. Finally, a pass/fail report is made, showing any issues for fixing.

Benefits of In-Circuit Testing for PCB Assemblies

In-circuit testing offers big perks for PCB assembly, addressing concerns like quality, cost, and speed.

Ensuring High-Quality PCB Assemblies

In-circuit testing PCB cuts building flaws, ensuring the best PCB assembly results. By checking each part alone, ICT spots issues like solder bridges, missing pieces, or wrong values early in production. This early catch lowers the risk of faulty products reaching buyers. ICT follows IPC-A-610 standards, a guide for quality in electronics building. For industries using PCB assembly services China, this ensures steady, high-quality PCBAs. Whether for everyday gadgets or critical medical tools, ICT promises that every board works reliably, building trust in the final product.

Time and Cost Efficiency with ICT

Automated in-circuit test methods are quick, usually taking one to two minutes per board. This speed lets builders test many boards without slowing production. By catching flaws early, ICT reduces the need for costly fixes, saving both time and money. For advanced circuits PCB assembly, this speed is vital, as complex boards are pricey to repair. As a PCB assembly service provider, using ICT boosts output and lowers overall costs. Thus, it’s a smart choice for large-scale production.

Applications of In-Circuit Testing in Modern Electronics

In-circuit testing is widely used across fields, ensuring trusty PCBAs in small and complex devices.

ICT in Consumer Electronics and Automotive Industries

In consumer electronics, in-circuit testing ensures PCBAs in phones, wearables, and tablets are free of flaws. These devices need high-density, small boards, where even tiny errors can cause failures. ICT checks part placement and circuits, supporting the best PCB assembly service for dependable gadgets. In the automotive field, ICT is key for advanced driver assistance systems, or ADAS, which rely on exact PCBAs for safety features like cameras and sensors. Advanced circuits PCB assembly in these sectors needs ICT to ensure performance under tough conditions. So, it’s vital for modern electronics building.

ICT for Medical and Aerospace Applications

Medical tools, such as pacemakers and imaging gear, need perfect PCBAs due to their life-saving nature. PCB in-circuit test ensures every part meets strict quality rules, lowering risks in medical uses. Likewise, aerospace systems like satellites and navigation tools depend on trusty PCBAs to work in harsh settings. In-circuit test supports PCB assembly services China by meeting tough industry needs. For these high-trust fields, ICT is essential, ensuring that every PCBA works perfectly, from design to use, in safety-critical uses.

Why Choose PCBAStore for PCB Assembly Needs?

PCBAStore stands out as a trusted provider of one stop PCB assembly services, with over 16 years of skill in PCB building and assembly. Their advanced ICT tools, including bed-of-nails and flying probe testing, ensure the best PCB assembly outcomes. Certified with ISO9001, PCBAStore delivers high-quality PCBAs for fields like medical, automotive, and consumer electronics. Their global reach and PCB assembly services China offer quick turnarounds with no minimum order amount, making them a dependable choice for businesses seeking efficient, high-standard PCBA solutions. Their focus on quality and accuracy supports smooth production and buyer happiness.

Frequently Asked Questions About In-Circuit Testing

This part answers common questions about in-circuit testing, giving clear insights for those exploring PCB assembly solutions.

What Defects Can an In-Circuit Test Detect in PCB Assemblies?

An in-circuit test spots flaws like short circuits, open circuits, missing parts, and wrong values, such as resistors or capacitors.

How Does ICT Differ from Functional Testing in PCB Assembly?

In-circuit testing checks single parts for building flaws, while functional testing looks at the overall work of a PCBA.

Is In-Circuit Testing Suitable for High-Density PCBAs?

Yes, in-circuit testing PCB works for high-density PCBAs, though complex designs may need flying probe testers for limited test spots.

What Are the Costs of Implementing ICT in PCB Assembly Services?

Using ICT involves upfront costs for custom fixtures, but it saves money by cutting rework. Automated in-circuit test is cost-effective for large-scale production, making it a wise choice for a PCB assembly service provider focused on efficiency and quality.

Take PCB Assembly to the Next Level

In-circuit testing is a game-changer for delivering trusty, high-quality PCB assemblies. By catching flaws early, ICT ensures that PCBAs meet the needs of modern electronics, from phones to medical tools. Partnering with a trusted PCB assembly service provider can lift production with advanced circuits PCB assembly. Ready to redefine electronics trust? Businesses can explore how in-circuit testing powers projects with accuracy. Visiting PCBAStore’s one stop PCB assembly services offers a chance to learn more and request a quote, ensuring top-tier PCBA solutions for any field.

Previous article:Double Sided PCB Assembly and Soldering: A Comprehensive Guide