General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

What is FR4 Circuit Board

Simon / 2021-03-29

Contents [hide]

Many electrical professionals and people dealing with electronic devices know the value of printed circuit boards (PCBs). These boards have transitioned traditional electronic devices to be simpler, high-quality, and enhanced their performance. In other words, PCBs have played an integral part in many electronic circuits and devices for a long time. Besides, electronic engineers also contemplate various materials employed in developing these boards. One such critical material is the FR4. FR4 is undeniably the ground or the backbone material popularly utilized in creating PCB boards.

Unfortunately, not everyone is aware of what FR4 entails, especially individuals with no prior experience. Therefore, this article seeks to give an insight into what FR4 circuit board entails, why it is a commonly used PCB base, why consider using it, and when to avoid utilizing the material.

What Is FR4 Circuit Board?

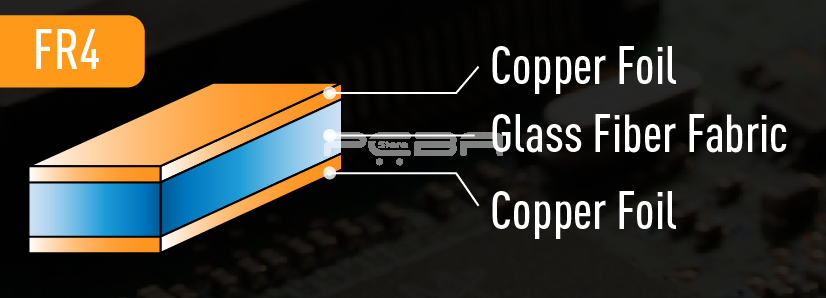

The FR4 circuit board is the standard name employed in PCB manufacturing. FR is the abbreviation of flame retardant. The value 4 is perceived as the typical rating of the material. The name FR4 is primarily employed in glass epoxy laminated sheets. This is something that appears to be woven and thin cloth sheets.

Basically, the FR4 circuit board is popularly considered to be a composite structure. Its fiberglass composition plays a critical part in providing the FR4 its essential structural stability. The fiberglass layer is based on the inner side, where it is bound and surrounded by epoxy resin that can resist flame. Epoxy resin is essential as it provides FR4 material the suitable rigidity.

Since FR4 works as the backbone of PCB, it is crucial to select the right FR4 material. Some of the available options include:

Standard FR4

FR4 High IRC

FR4 High TG

FR4 no copper

While choosing FR4 circuit board material, there are some aspects that you must keep in mind. One such aspect is the FR4 board thickness measured in inches, thousand, or millimeters.

Usually, the suitable FR4 material must be thin to help develop a PCB board with limited space. The reason to consider thin material is that it can accommodate many fragile components needed to create devices like USB connectors, Bluetooth devices, and other items using PCB boards. Thin FR4 material is yet ideal for creating larger devices where space-saving design is required.

Alternatively, thin FR4 material is best applied in flexible devices. For example, employing a thin FR4 material for medical and automotive PCB boards is appropriate since these boards demand consistent flexing.

Consequently, avoid selecting thin FR4 because it can initiate a higher risk of board fracture or damage.

Furthermore, the thickness of the FR4 material can influence the weight of PCB as well as the compatibility of the components.

The Difference between FR4 Material and Rogers Material

There are several manufacturers and suppliers that employ various materials while creating your PCB boards. Some excellent materials used are FR4 or Rogers. However, there are distinguishing aspects between the two materials.

1. Price

Materials used in creating PCB boards differ significantly; however, the price for these materials matters as twice. Rogers and FR4 materials vary in terms of price. The cheapest is the FR4. FR4 material is low cost and is most loved by manufacturers due to its low processing costs. Even if FR4 materials create low-performing PCB boards, they are cheaper than their counterparts. If you ponder the processing requirement and the overall price of the content, then it is possible to evaluate the value of your cash.

In most cases, PCB boards from FR4 materials are designed for people on a budget. However, if the price isn't bothersome, it is better to consider the board created using Rogers materials. With that in mind, it is better to remember that cheap can always be expensive.

2. High frequencies

The great thing about FR4 materials is that they are relatively cheap, reliable, and easy to understand mechanical and electrical traits. They can be used in many devices, including audio circuits and microwave designs. Regrettably, FR4 material isn't the suitable material to create PCB boards for applying in high-frequency. On the other hand, Roger's material is the best employed in creating PCB boards that require high frequencies.

3. Df/Dissipation

Material and the cost of the PCB are not the only determinants when evaluating its value and performance. Df or the loss factor are also determinants. Usually, the Df PCB board created using FR4 materials can be minimized or influenced. If you compare FR4 PCB boards with Rogers PCB boards, you will find that the Roger option will have more significant losses. In simple terms, FR4 materials possess a high Df aspect than the Rogers counterparts, particularly at high frequencies. Basically, FR4 materials can be recognized by Df that rises when there is an increase in frequency. Where FR4 possesses low Df, there is a reduction in signal losses, and their manufacturing is easy.

4. Impedance stability

Despite being relatively cheap, FR4 materials are highly prone to different dielectric constant, which occurs across the substrate's length and width plus temperature change. If we consider impedance stability, you will realize that Roger's material has a significant dielectric constant range than its counterpart. In cases where high frequencies and temperature change are necessary, it is recommended to employ Roger's material.

5. Dielectric constant

This is an aspect or quantity that evaluates the possibility of storing a significant amount of electric energy. For the dielectric constant, Rogers has a higher dielectric value of 6.15 to 11 than FR4 material with a dielectric value of 4.5. This means that if you consider FR4 material, you can save up to 25% of the material than the counterparts. Other great things about FR4 are that they are water-resistant, lightweight, and has high dielectric strength.

6. Space application

The materials employed in creating a PCB board for space exploration matters the most. Not every PCB material will give extraordinary functionality. Rogers and FR4 materials are two kinds of materials that differ significantly in this application. In space exploration, you will find outgassing, which occurs when gas is trapped and released in the form of powder coating. This can cause moisture content or corrosive material to penetrate the board's surface and damage some parts. FR4 material will give incredible balance for manufacturability, cost, electric stability, and durability. The right option for space application can be Rogers due to its low outgassing characteristics.

7. Temperature management

The materials used to develop PCB boards are gauged or characterized by dielectric constant, best referred to as thermal coefficient. FR4 has a relatively smaller number of around 200 million/degree Celsius, introducing an excellent temperature variation range. If PCB boards employ small variation over a high range of temperature, then it could be great to consider Roger material over FR4 material.

Benefits of FR4 Circuit Board

There are many overwhelming reasons to consider using the FR4 circuit board. Often, these boards are water-resistant, sturdy, and offer exceptional insulation. This occurs at the copper layer that reduces interference and backs great signal integrity. Other benefits of using FR4 circuit boards are that:

They are cheap materials

Possess powerful dielectric signal that plays an integral role in electrical insulation

They are lightweight and possess an incredible strength vs. weight ratio

The material possesses outstanding electric loss characteristics

They are light green or yellow in color, making them great for any appliance

When to avoid employing FR4 Material for Circuit Board

As we have discussed above, FR4 material is undeniably a great option to use as the PCB board base. This is true because most engineers consider it default or standard choice for their board material. However, there are instances where this material should be avoided. These cases can be:

Where you need lead-free soldering

Most boards you find in Europe are RoHS compliance. They also must be in compliance with the client's desires. This means that if the client wants lead-free soldering to be employed, you must consider other alternatives. This is because no-lead PCB boards require you to use 250 degrees Celsius, which can be relatively high to the Tg of most FR4.

High-frequency signal requirement

One thing that makes FR4 board material relevant is the impedance traits. However, when exposed to high frequencies, this property is influenced and thus, negatively affects the integrity of the signal.

Great temperature resistance

If you are going to develop a PCB board in a high-temperature environment, it would be pointless to employ FR4 material. For example, it is not advisable to utilize FR4 material in developing PCB boards for aerospace applications.

Conclusion

FR4 is undeniably one of the best and popularly used materials in the construction of PCB boards. The boards created using FR4 material are perceived to be water-resistant, strong, and offer fantastic insulation, reducing interferences and backs excellent signal integrity. You need to remember that in a high-temperature environment and frequencies, FR4 can be the wrong choice. Therefore, the good thing is that to land the best PCB board or develop a great board, you need to reach out to the manufacturer to discuss the right type or the requirements.

Previous article:13 Common Used Circuit Board Components Explained