General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

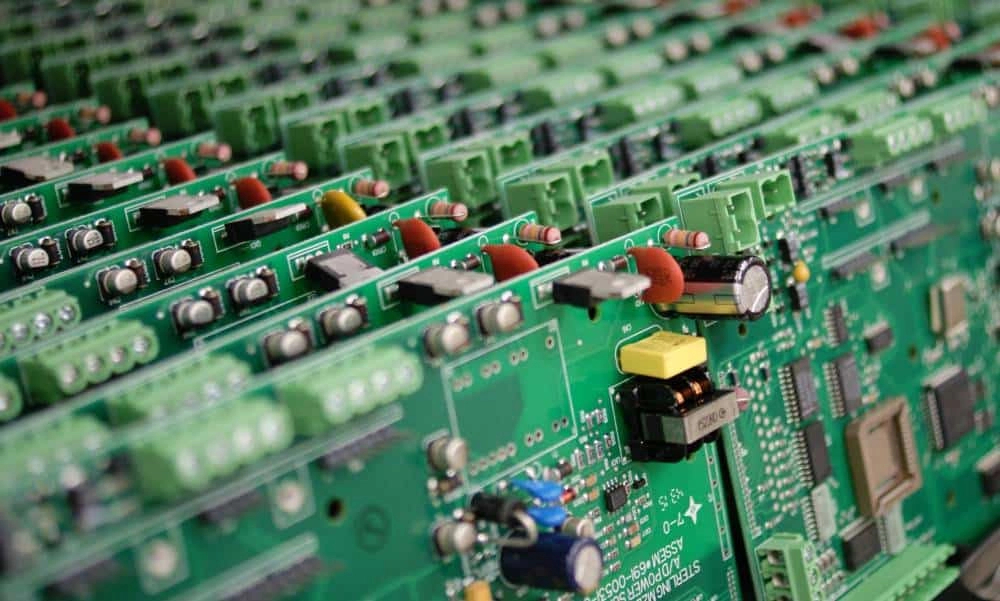

Low Volume vs. High Volume PCB Assembly Manufacturing

PCBA Store / 2025-06-20

Contents [hide]

What is Low Volume PCB Assembly

Characteristics of Low Volume PCB Assembly

Production Quantities and Scale

Low volume PCB assembly means making a small number of printed circuit boards. This usually ranges from a few to several hundred boards. It is perfect for testing designs, small production runs, or special uses. These uses do not need large amounts. The small scale lets manufacturers focus on accuracy and custom work instead of mass production.

Customization and Flexibility in Design

A key feature of low volume PCB assembly is its ability to handle custom designs. Manufacturers can quickly adjust to unique customer needs. These include specific layouts, materials, and parts. This adaptability makes it a top choice for industries like medical devices, robotics, and consumer electronics. These fields often need custom solutions.

Advantages of Low Volume PCB Assembly

Cost-Effectiveness for Prototyping

Low volume PCB assembly is very budget-friendly during the testing phase. By making only a small batch of boards, companies can test their designs. They can make changes without spending on large-scale production. This method reduces waste. It also ensures design errors are fixed before making more boards.

Reduced Lead Times for Small Orders

Low volume PCB assembly involves fewer boards. This often leads to quicker completion times. This speed is vital for businesses wanting to launch products fast or meet tight deadlines. Many manufacturers offer fast services. These can deliver test boards in just a few days.

Challenges in Low Volume PCB Assembly

Higher Per-Unit Costs

A big challenge of low volume PCB assembly is the higher cost per board. Without the savings from large-scale production, setup costs are spread over fewer boards. This makes each board more expensive.

Limited Automation Opportunities

Due to the smaller scale, low volume PCB assembly often uses manual methods instead of full automation. This can increase labor costs. It may also cause slight differences compared to automated high volume production lines.

What is High Volume PCB Assembly

Features of High Volume PCB Assembly

Large Scale Production Capabilities

High volume PCB assembly focuses on making thousands or even millions of boards. This manufacturing is built for mass production. Consistency and efficiency are key. Industries like automotive and telecommunications often use high volume assembly. They need it for their large product demands.

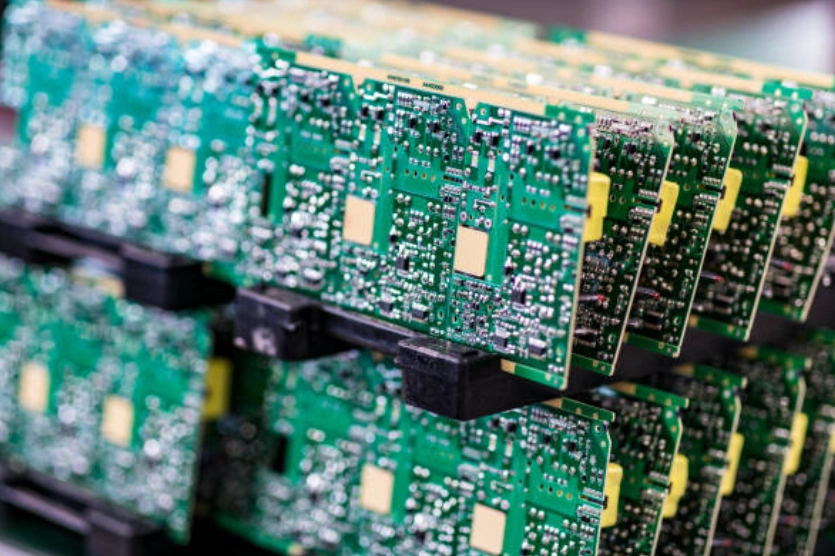

Standardization in Processes

High volume PCB assembly uses standard processes. These ensure all boards are the same. Automated machines and strict quality checks are key parts of this method. These standards keep performance steady across large numbers of boards.

Benefits of High Volume PCB Assembly

Cost Efficiency in Bulk Production

A major benefit of high volume PCB assembly is its cost savings. By spreading setup costs over many boards, manufacturers lower the cost per board. This makes it a great choice for products with high demand.

Consistency and Quality Control

High volume assembly uses advanced automation. This improves consistency and quality. Automated inspection systems, like AOI (Automated Optical Inspection), ensure each board meets high standards.

Drawbacks of High Volume PCB Assembly

Longer Setup Times

Setting up machines for high volume production takes a lot of time and resources. This long setup can delay early production compared to low volume methods.

Reduced Flexibility for Custom Designs

High volume PCB assembly focuses on standard processes. This can limit custom options. Changing designs or adding unique features may need big changes to set processes. This can raise costs and delay delivery.

Factors to Consider When Choosing Between Low and High Volume PCB Assembly

Project Requirements and Objectives

Choosing between low and high volume PCB assembly requires understanding your project’s needs. Low volume PCB assembly is great for testing designs, small production runs, or special uses. These do not need large quantities. It allows more flexibility for design changes and testing. This makes it ideal for startups or companies creating new products.

In contrast, high volume PCB assembly is for making thousands or millions of boards. It suits products with steady market demand. Industries like medical devices and robotics often need low volume assembly. They require custom solutions. However, sectors like automotive and telecommunications benefit from high volume assembly. They need its standard processes and efficiency. Checking the PCB’s end use and custom needs helps pick the best option.

Budget Constraints and Cost Analysis

Budget is a key factor in choosing between low and high volume PCB assembly. Low volume PCB assembly is budget-friendly for testing. By making a small batch, companies can test designs without high production costs. However, a big challenge is the higher cost per board. Setup costs spread over fewer boards make each one more expensive.

On the other hand, high volume PCB assembly saves money in bulk production. The savings from large-scale production lower the cost per board. This is appealing for products with high demand. Companies must balance the initial investment with long-term savings when choosing high volume production.

Timeframe and Delivery Expectations

Delivery time is another important factor. Low volume PCB assembly often has faster completion times. This is crucial for businesses needing to meet tight deadlines or launch products quickly. Many manufacturers offer fast services. These can deliver test boards in days. This ensures minimal delays during development.

In contrast, high volume PCB assembly needs more time for setup. The long setup can delay early production runs. However, it ensures consistent quality across large quantities once running. Businesses with flexible timelines may accept this trade-off for long-term benefits.

Why Choose PCBAstore

PCBAstore is a trusted partner for both low and high volume PCB assembly needs. It has 16 years of experience in PCB fabrication and 8 years in assembly services. PCBAstore offers full electronic manufacturing solutions. These suit industries like robotics, medical devices, automobiles, communication systems, and consumer electronics.

A key strength of PCBAstore is its one-stop solution. It covers PCB design, layout, testing, and mass production. This ensures smooth integration at every stage.

For low volume projects, PCBAstore offers fast prototyping services. These deliver quick-turn PCBs at good prices. Customers benefit from short lead times without losing quality. For high volume needs, PCBAstore uses automated processes. These achieve cost savings while keeping strict quality standards through IPC Class 2-3 compliance.

PCBAstore also provides excellent customer support. It offers instant online quotes and fast delivery options, as quick as 24 hours. It has a 100% refund policy for quality issues. Their global customers prove their reliability as a trusted printed circuit board supplier based in Shenzhen, China’s Silicon Valley.

By choosing PCBAstore, businesses gain a partner focused on innovation, efficiency, and excellence in electronic manufacturing services.