General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

Medical PCB Solutions: From Design and Manufacturing to Assembly

PCBA Store / 2026-01-22

Contents [hide]

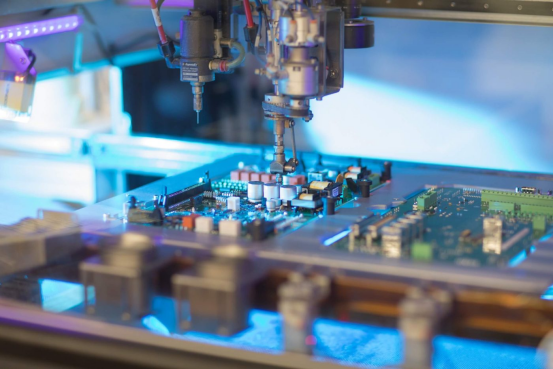

Printed circuit boards (PCBs) act as the base for many electronic devices in today's healthcare. Medical PCBs run diagnostic tools, monitoring setups, imaging equipment, wearable health devices, and surgical tools. Here, steady performance directly affects patient safety and treatment results. These boards need very high accuracy, strong build, and full agreement with tough rules. They must work perfectly in situations where lives are at stake. From small layouts that use high-density interconnect (HDI) technology to solid multi-layer builds, medical PCB solutions combine modern materials and careful steps. This helps meet the strict demands of the industry.

PCBA Store, a leading manufacturer and supplier of PCBs and PCBA services based in Shenzhen, China, offers complete solutions made for tough areas like medical electronics.

Why Medical PCB Solutions Matter in Healthcare

Medical devices depend on PCBs that work without any breakdown in hard conditions. Just one fault in a heart monitor, defibrillator, or infusion pump can cause serious problems. Reliability is the main focus. It pushes the need for top-quality making and putting together. These must handle sterilization, changes in temperature, and nonstop use.

Following rules is another key part. Standards like ISO 13485 for quality management in medical device production, plus IPC-6012 Class 3 for high-reliability electronics, help keep performance steady. Many uses also need biocompatibility for items that touch the body. They require RoHS compliance for environmental protection. Plus, they follow FDA or CE marking rules when needed.

Making things smaller is very important for portable and implantable devices. HDI technology allows smaller sizes with more parts packed in. This supports new ideas in telemedicine, remote checks, and point-of-care testing.

Designing Medical PCBs: Precision from the Start

Good medical PCB design starts by following rules and performance needs.

1. Meeting Regulatory Standards

Designs include needs from ISO 13485, IPC-6012 Class 3, and related biocompatibility guides. Paperwork tracks each step. This makes audits and certifications easier. High-reliability parts lower risks in devices that touch patients.

2. Incorporating HDI Technology

HDI uses microvias, blind and buried vias, and thin traces (as low as 2-3 mils). This creates high part density. The method boosts signal quality with close impedance control (±10% tolerance). Such control is vital for weak signals in ECG machines or imaging setups. Sequential lamination helps build complex multi-layer boards.

3. Thermal and Electrical Performance

Materials such as high-Tg FR-4 or polyimide deal with heat stress from sterilization. Electrical features handle high-frequency signals (up to 10 MHz or more). They also manage heat spread in small cases. Impedance-controlled traces make sure data moves correctly in diagnostic tools.

Manufacturing Medical PCBs: Quality in Every Layer

Making turns designs into dependable boards with careful steps.

1. Material Selection

High-grade laminates have raised glass transition temperatures (Tg 170°C+). They stand up to heat in autoclaving. Lead-free and halogen-free choices follow RoHS. They also help with biocompatibility. Special bases like Rogers or aluminum types meet certain RF or heat needs in medical imaging.

2. Advanced Fabrication Techniques

Laser drilling makes microvias as small as 0.075-0.1 mm. Sequential lamination creates boards with up to 40+ layers. It keeps alignment exact. Things like heavy copper (up to 6-30 oz), via-in-pad, and back-drilling improve results in high-power or crowded setups.

3. Rigorous Quality Control

Automated optical inspection (AOI), electrical checks for impedance and continuity, and very low defect goals (<0.1% failure rate) confirm quality at each point. X-ray checks find hidden problems in tight layouts.

Turnkey PCB Assembly: Simplifying the Process

Turnkey assembly makes production smoother. It covers everything from getting parts to final checks.

1. What is Turnkey PCB Assembly?

This service finds parts, puts boards together, and does checks all in one place. It cuts lead times—prototypes can come in just 8-48 hours. It also lowers supply chain risks for medical work that needs trackable parts.

2. Surface Mount and Through-Hole Assembly

SMT puts small parts (down to 01005 packages) with great accuracy (0.01 mm placement). THT manages strong connectors. Mixed methods use both for flexible designs. Lead-free soldering follows RoHS standards.

3. Testing and Validation

In-circuit testing (ICT) looks for shorts and opens. Functional testing copies real use. Environmental stress screening puts boards through temperature swings (-20°C to 85°C) and shaking. X-ray and AOI confirm solder joints are good, especially on BGA and QFN packages.

Challenges in Medical PCB Solutions and How to Overcome Them

Making things smaller tests limits on trace widths and via sizes. Advanced HDI skills and skilled partners handle these needs.

Strict rule-following calls for complete paperwork. Manufacturers with solid quality setups give help for audits and tracking.

Supply chain issues change part access. Turnkey services with steady sourcing and stock control reduce delays.

Benefits of Partnering with Experts for Medical PCB Solutions

Skilled partners give full control from start to finish. They provide access to HDI and modern materials. They also bring quicker prototypes and lower costs through better methods. Guidance on rules and strong on-time delivery help keep projects on schedule.

Future Trends in Medical PCB Solutions

Flexible and rigid-flex PCBs allow wearables and implantable devices to have very thin shapes (down to 0.1 mm). IoT links add wireless features for remote checks. AI-powered processing needs fast signals (5 Gbps+) and better signal quality in small sizes.

Conclusion: Reliable Medical PCB Solutions for Healthcare Innovation

Medical PCBs need careful work in design, manufacturing, and assembly. This ensures safety and good performance in key uses. From compact HDI layouts to strict checks in turnkey steps, the whole process meets needs of current healthcare devices.

PCBA Store provides full-range PCB fabrication and PCBA services. These include features fit for medical electronics such as HDI, multi-layer boards, turnkey assembly, and quality checks that match industry standards.

FAQ

What standards apply to medical PCBs?

Medical PCBs typically comply with ISO 13485 for quality management, IPC-6012 Class 3 for reliability, RoHS for environmental safety, and additional regulations like IEC 60601-1 or FDA requirements depending on the device classification.

Why is HDI technology important for medical devices?

HDI enables miniaturization with microvias and fine traces. It improves signal integrity and component density. These are essential for portable monitors, wearables, and diagnostic tools.

What materials work best for medical PCBs?

High-Tg FR-4, polyimide, halogen-free laminates, and specialty substrates like Rogers support thermal resistance, biocompatibility, and high-frequency performance.

What is turnkey PCB assembly?

Turnkey assembly handles component sourcing, SMT/THT placement, soldering, and testing as a complete service. It reduces lead times and supply risks.

How are medical PCBs tested for reliability?

Testing includes AOI, X-ray inspection, ICT, functional verification, and environmental stress screening. These ensure performance under operational and sterilization conditions.

Partner with PCBA Store for Medical PCB Needs

PCBA Store operates as a direct manufacturer, supplier, and factory specializing in PCB fabrication and PCBA services. With over 16 years of experience in PCB production and 8 years in assembly, the facility in Shenzhen delivers high-reliability solutions for medical electronics and other sectors. Capabilities include 1-40 layer boards, HDI, rigid-flex, turnkey assembly, instant online quotes, no MOQ, express turnaround (8-48 hours for urgent needs), and quality systems aligned with ISO9001.

For medical device projects requiring precision, compliance support, and cost-effective production, contact PCBA Store today. Upload designs for an instant quote at https://www.pcbastore.com/online_quote.html or email svc@pcbastore.com. Start the collaboration to bring reliable medical PCB solutions to market efficiently.