General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

The Advantages and Disadvantages of Surface Mount Technology in PCB Assembly

PCBA Store / 2025-05-22

Contents [hide]

Surface Mount Technology, or SMT, is an essential approach in current electronics production. It permits parts to be attached directly to the surface of a printed circuit board, resulting in tinier and more effective gadgets. From smartphones to medical tools, SMT is vital in advanced circuits PCB assembly. This article will describe the upsides and downsides of SMT. It will aid engineers, designers, and companies in deciding if SMT suits their PCB SMT assembly projects. By grasping SMT, you can make wiser decisions for your electronic creations. This ensures the best PCB assembly outcomes.

What is Surface Mount Technology (SMT)?

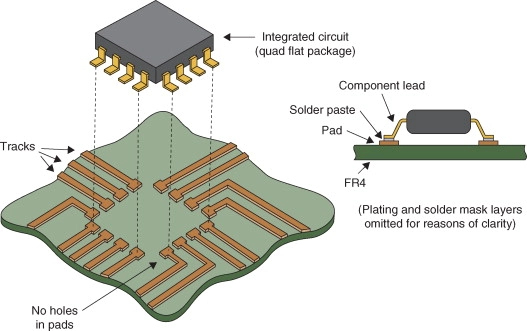

Surface Mount Technology is a technique for constructing electronic circuits. It involves placing parts directly on a PCB’s surface. Unlike older through-hole methods, which need holes drilled and component leads inserted, SMT attaches parts to the board’s exterior. This makes it a preferred option for SMT PCBA manufacturing. It is common in fields like consumer electronics, automotive, and medical devices. Why? It supports small and intricate designs. SMT gained traction in the 1980s. Now, it leads PCB SMT assembly processes because it creates smaller, quicker, and more dependable circuits. For companies seeking the best PCB assembly service, SMT enables high-density boards that meet today’s needs.

Key Features of SMT in PCB Assembly

SMT has several notable traits that make it excellent for China SMT PCB assembly. First, it uses leadless or short-lead parts. These save room and boost function. Second, it depends on automated tools, like pick-and-place machines. These place parts swiftly and precisely. This automation enhances efficiency in SMT PCBA processes, particularly for complex layouts. Lastly, SMT allows parts on both sides of the board. This enables denser and more detailed circuits in advanced circuits PCB assembly. These qualities make SMT a popular choice for modern electronics.

Advantages of Surface Mount Technology in PCB Assembly

SMT is favored for best PCB assembly services. It provides many benefits that match today’s demand for small, rapid, and budget-friendly electronics. Whether you’re designing a smartphone or an automotive system, SMT creates high-quality boards efficiently. Its strengths make it a leading option for PCB assembly services in China and elsewhere. It supports trends like miniaturization and high-speed function. Let’s explore why SMT is widely used in SMT PCBA manufacturing.

Miniaturization and Compact Designs

One major strength of SMT is its ability to create smaller and lighter PCBs. Compared to through-hole technology, SMT parts are 60–90% smaller in size and weight. This enables SMT PCB assembly processes to produce tiny devices like smartphones, wearables, and medical tools. By fitting more parts into less space, SMT meets the need for compact electronics without losing performance. This is ideal for industries that value space-saving designs in PCB SMT assembly.

Enhanced Manufacturing Efficiency

SMT simplifies production. It is a top pick for PCB assembly service providers. Unlike through-hole methods, SMT skips drilling holes. This reduces setup time. Automated tools, like pick-and-place systems, position parts quickly and accurately. This speeds up the PCB SMT assembly process. The efficiency cuts labor costs. It also lets manufacturers produce boards faster. For companies seeking the best PCB assembly service, SMT’s automation ensures quicker delivery and dependable results.

High Signal Transmission and Performance

SMT excels at providing fast and reliable function, especially in advanced circuits PCB assembly. SMT parts have short or no leads. This reduces signal interference and supports rapid transmission. It is perfect for industries like telecommunications and automotive, where performance is critical. SMT boards also resist vibration and tough conditions. This ensures durability in China SMT PCB assembly projects. Such reliability is vital for high-performing electronics.

Cost-Effectiveness and Scalability

SMT is budget-friendly. It cuts material and labor costs by 30–50% compared to through-hole methods. This makes it a great choice for PCB assembly services in China, where high-volume production is common. SMT’s automated processes allow manufacturers to scale up easily. They can produce many boards without losing quality. For businesses seeking affordable yet reliable SMT PCBA manufacturing, SMT provides a cost-effective solution that meets industry standards.

Disadvantages of Surface Mount Technology in PCB Assembly

While SMT offers many upsides, it also has drawbacks. Engineers and companies must consider these. Understanding these challenges ensures successful SMT PCBA processes. Despite its popularity in PCB assembly services in China, SMT isn’t ideal for every project. Let’s examine its limitations to provide a fair view of SMT advantages and disadvantages.

Technical Complexity and High Initial Investment

SMT requires advanced tools, like reflow ovens and pick-and-place machines. These can be costly. The high startup cost can be a hurdle for small companies or low-volume projects in PCB SMT assembly processes. New businesses may struggle to afford the equipment needed for SMT PCBA manufacturing. This is especially true if they only need a few boards. This complexity makes SMT less practical for small-scale production.

Challenges in Inspection and Repair

Inspecting and fixing SMT boards is tough. The parts are tiny, and solder joints are dense. Visual checks often fall short. Advanced tools, like X-ray inspection, are needed to find issues like solder voids. This complicates quality control in SMT PCBA processes, even for the best PCB assembly providers. Repairs are also tricky. Small parts are hard to handle. This increases the risk of mistakes during fixes.

Fragility and Power Limitations

SMT parts are delicate. They can break easily during handling or use. This is a concern for PCB SMT assembly. Mishandling can damage fragile components. Also, SMT isn’t ideal for parts that produce high heat or handle heavy electrical loads. Heat can melt solder joints. This limits SMT’s use in some applications. It may not suit certain advanced circuits PCB assembly projects compared to through-hole methods.

Best Practices for Optimizing SMT PCB Assembly

To maximize SMT’s benefits, companies and engineers can follow key strategies. These improve quality and reduce challenges. These approaches ensure reliable SMT PCBA manufacturing. They make SMT a top choice for PCB assembly services in China. By planning carefully, you can boost SMT’s strengths and avoid common issues.

Efficient PCB Layout Design

A well-planned PCB layout is vital for successful SMT PCB assembly processes. Using Design for Manufacturability (DFM) guidelines helps position parts to reduce errors. It also improves solder joint reliability. A balanced layout prevents warping during soldering. It ensures smooth assembly. This approach lowers costs. It also enhances the quality of best PCB assembly services. It makes producing high-performing boards easier.

Choosing the Right Components

Picking low-profile, standard parts simplifies placement. It also improves compatibility with advanced circuits PCB assembly. Low-profile parts save space. They reduce interference between components on both sides of the board. Choosing suitable parts ensures smoother SMT PCBA processes. It helps manufacturers deliver reliable, high-quality boards that meet project needs.

Why Choose PCBAStore for Your SMT PCB Assembly Needs?

For companies seeking dependable one-stop PCB assembly services, PCBAStore is a trusted partner. With 16 years of experience, PCBAStore provides high-quality China SMT PCB assembly. They use advanced tools like reflow ovens and pick-and-place machines. Their expertise covers prototyping to mass production. They serve industries like medical, automotive, and consumer electronics. PCBAStore ensures cost-effective and reliable SMT PCBA manufacturing. They focus on quality, backed by ISO9001 certification. Their team manages everything from component sourcing to final testing. This makes them a top pick for PCB assembly service providers.

Conclusion: Is SMT Right for Your PCB Assembly Project?

Surface Mount Technology offers strong benefits for PCB SMT assembly. It enables smaller designs, faster production, better performance, and lower costs. However, challenges like high setup costs, delicate parts, and inspection difficulties mean it’s not ideal for every project. Companies should weigh these SMT advantages and disadvantages. This helps decide if SMT fits their needs, whether for advanced circuits PCB assembly or simpler designs. Ready to enhance your next electronics project with cutting-edge PCB SMT assembly? Connect with PCBAStore’s experts. They offer tailored one-stop PCB assembly services at https://www.pcbastore.com/.