General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

What Is PCB Surface Mount Technology (SMT)

Simon / 2021-02-24

Contents [hide]

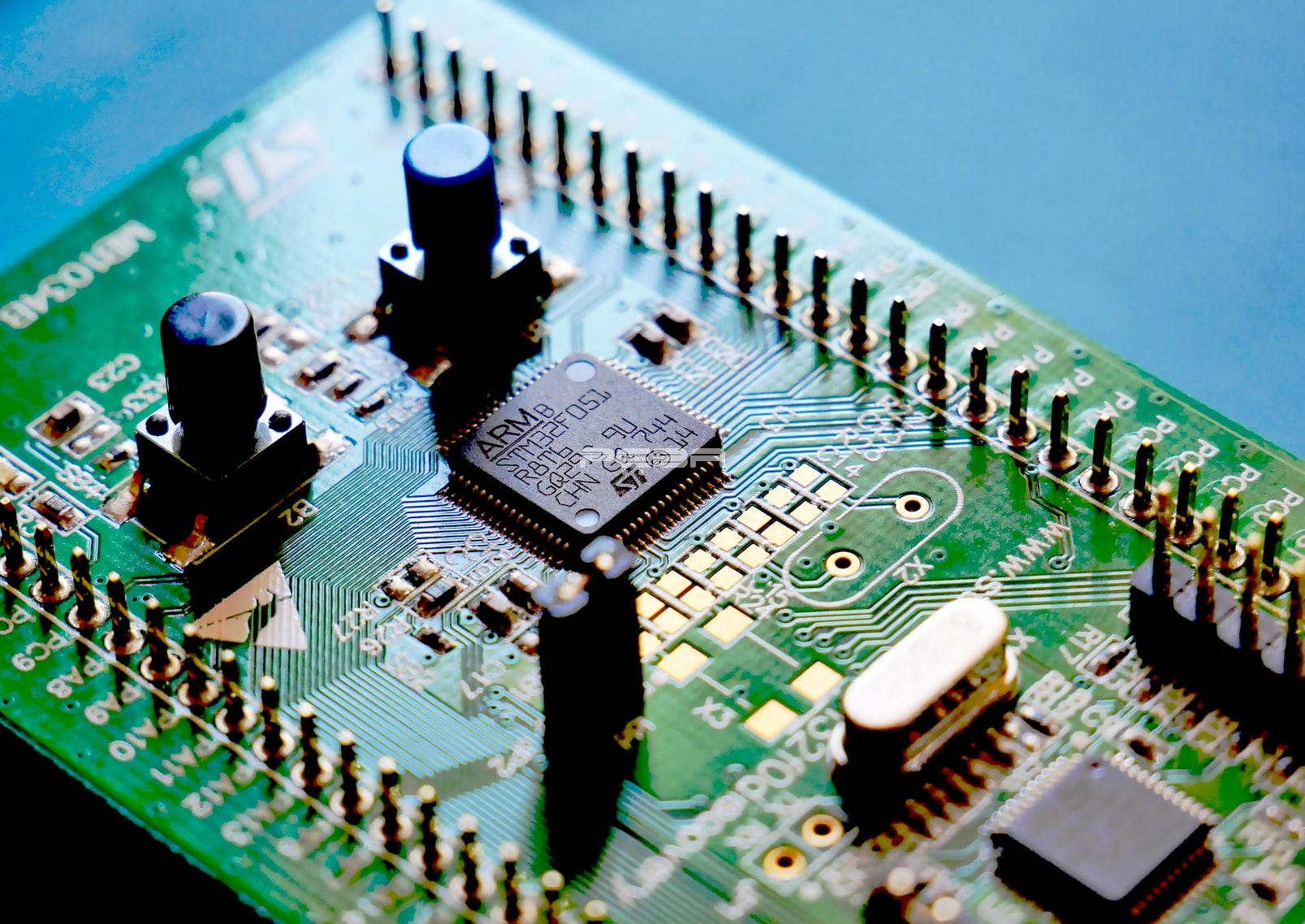

You all can attest that electronic types of equipment are nowadays employing smaller devices than their traditional electronic equipment counterparts. Traditional types utilize wire leads to connect components from one section to another similar to the idea used for kits and home construction. Alternatively, today's electronic equipment uses small components that are mounted on the board's surface to serve a similar purpose. This is made easy through a technology referred to as the SMT or (surface mount technology). Technically, all the electronic equipment designed today employs this technology since it provides an enormous benefit when it comes to the PCB process. The technology also gives a significant benefit since the perception of using minute SMT components allows several electronics to be accommodated in a somewhat smaller space. Besides offering enough space, SMT enables the soldering process and automated PCB assembling to be easy; thus saving the overall cost and boosting reliability.

What is Surface Mount Technology (SMT)?

Surface mount technology is a complex circuitry technique of mounting components onto PCB surfaces. It is a modern technique that has hugely replaced traditional through-hole technology in different electronic equipment. Traditional through-hole technology with leads employed since the 1980s made it daunting when assembling PCB boards. The components used such as capacitors and resistors required leads to integrate the circuit and fit them through holes. These processes needed lead to be fitted at the correct pitch to foster easy replacement through holes.

This method was rather challenging to handle since lead didn't fit the holes that become tight over time. This issue led to the frequent intervention of the devices to solve the problem of unfitting components that made machines stop working. The approach also dragged the assembly of PCB and significantly leads to increased costs.

With the PCB assembly, the process doesn't employ the passing of the lead via the board. Rather, it encompasses soldering elements or components onto the board directly. This led to the discovery of SMT PCB technology that utilized SMT components and since then, the benefits of this technology have been witnessed. Currently, it is the primary technology employed in manufacturing electronics and assembling PCB. This is made easy by many SMT components, including SMT resistors and SMT capacitors, passive SMDS, diodes, integrated circuits, transistors, among others.

The Differences between SMT PCB & SMD PCB

Fundamentally, SMD PCB and SMT PCB are different. Surface mount technology (SMT) is a process while surface mount device is the device. In simple terms, SMT encompasses the whole process of soldering and mounting electronic elements, including capacitors, integrated circuits, resistors, transistors, among others onto the PCB board. The elements or components employed in this process are what can be considered as the SMD. It must be understood that the surface mount technology can work without reserving components for via hole pins. Additionally, surface mount devices are minute compared to the through-hole incorporation process.

To help distinguish the two clearly, let us have a look at the features that make up SMT:

Components used don't possess lead or can utilize short leads

The PCB board has both the solder joint and the component's body on the same side.

Features of the surface mount devices are:

No lead

Miniaturization

Ideal for PCB surface assembly

Initially, electronic manufacturers used hands to solder surface mount devices. This was actually simple for the first group of components, making it difficult to place or handle the other batch of elements. The process became more complicated as several minute items were required to be manually placed on the board. With the discovery of SMD, the process becomes easier as every through-hole element has embraced the SMT technique.

The Process of SMT PCB Assembly

The process of manufacturing PCB devices employing SMT encompasses assembling electronic elements by use of an automated machine. This machine places these elements on the board surface but before this happens, the PCB files have to be checked to confirm that they have no issues that can influence the manufacturability and functionality of the devices. After confirming everything is perfect, the process of SMT PCB assembly is not limited to soldering and placing elements or compounds on the PCB board but the following production process has to be followed.

Apply solder paste

The initial step when assembling the SMT PCB board is applying the soldering paste. The paste can be applied to the PCB via silk screen technology. It can also be applied using PCB stencil tailored from a similar CAD output file. You only need to cut the stencils using a laser and apply the soldering paste to the parts where you will solder the components. The solder paste application must be carried out in a cool environment. Once you are done applying, you can wait for some time for assembly.

Inspection of your solder paste

After applying the solder paste onto the board, the next step is always inspecting the latter via the solder paste inspection technique. This process is essential especially when analyzing the location of your solder paste, the amount of solder paste used, and other basic aspects.

Process confirmation

Just in case your PCB board is utilizing SMT components on either side, there will be a need to consider repeating the same process for secondary side confirmation. Here, you will be able to track the ideal time used to expose the solder paste to room temperature. This is the time your board will be getting ready for assembly. The components will still be getting ready for the next factory.

Assembly kits

This basically deals with BOM (Bill of materials) that are taken by CM for data analysis. This helps to develop a BOM assembly kit.

Stocking kits with elements

Pulling of the element from stock is done by use of bar codes and included in the assembly kit. When the kit is completely loaded with components, it is taken to the machine referred to as the pick-and-place for surface mount technology.

Preparation of components for placement

A pick-and-place tool is employed here to hold every element for assembly. The machine also uses a cartridge that comes with a unique key that corresponds to the BOM assembly kit. The machine is designed to tell the part that the cartridge hold.

The Advantages of SMT PCB Assembly

There are many befits of SMT PCB assembly and in order to realize these benefits, the SMT needs formality. This assembly possesses particular needs for the design part as unique PCB tools are required. After the assembly process is complete, a single board testing will follow. The reasons that make SMT PCB assembly beneficial are as follows;

Saves money

One great reason to consider embracing SMT assembly is affordability fostered by low manufacturing cost. The technology uses less holes on the board. Fewer holes mean that the processing cost will be lower. Alternatively, it will be easier to create high volumes, ensure that per-unit cost is better.

Efficiency

Another overwhelming reason to consider using SMT assembly is the circuit board space employed in a greatly efficient manner. The technology also enables manufacturers to create complex electronic devices and customize them into small devices. Furthermore, SMT assembly is quicker; thus enables engineers and/or manufacturers to boost total output. Simply put, a process that requires a minimum of 1-2 hours using the traditional technique can only take 10-15 minutes using SMT assembly.

Simplicity

In the traditional through-hole technique, the lead wire is used to connect electrical components. In SMT PCB assembly, the connection of components is done by soldering them to the board; which makes the overall process simple.

Error-free

The great thing about the SMT assembly technique is that it is reliant on electrical machines and/or devices. For that reason, cases of errors are minimal since everything is often automated.

Reduces weight and size

When components are soldered onto PCB board directly, there is a lot of space saved that maintains the performance and reliability of the board while minimizing weight and size.

SMT PCB Applications

Many amazing benefits of SMT have led to many fields embracing this technology. Despite being used for home construction needs, proper care is needed when it comes to soldering these SMT components. Furthermore, great care is required especially when soldering components such as integrated circuits. Basically, components having 5 or more pins can be challenging to solder until special equipment is used.

Even so, surface mount technology components can be employed for specific home projects. This is especially where SMT elements connections and leads aren't minute to handle many tools like traditional soldering irons among others.

Conclusion

The SMT assembly process is transforming PCB fabrication and taking it to the next level. It is such a cost-effective, efficient, and trusted technique for creating PCB. The only thing expected in the future is of course improvement of the whole SMT PCB technology since it is not an easy process. The good thing is that even today, you can get reliable PCB boards at cost-friendly rates. Notwithstanding, it is worth reaching out to reliable engineers or manufacturers with ideal equipment and experience to meet the requirement of your board. To help you know the best manufacturer, you can always consider the ones using modern equipment, top-notch materials, affordable rates, and on-time delivery.

Previous article:Circuit Board Transistor Explained in Detail