General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

All You Need to Know About Solder Paste

Simon / 2021-05-08

Contents [hide]

Printed circuit boards (PCBs) form the core component of any electronic device. Yes, starting from your TV to your dishwasher to your cell phone to your Alexa, every contemporary electronic equipment comprises this basic building block.

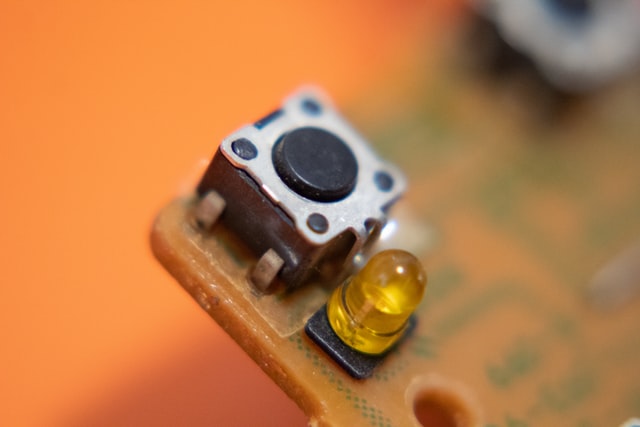

Talking about PCBs, they contain minute components that need to be placed together on the board and connected logically for the electronic appliance to function. Have you ever wondered how these tiny components are held together on the board?

The answer is simple. They must be glued to the board by some form of adhesive. Well, yes, and no. PCBs have to last long and withstand the flow of electricity. But just any adhesive won't do. So, what makes them stick to the board?

Engineers who work on PCB assembly typically use a specific form of paste to hold the components of the board together. This paste is known as solder paste.

Now, what is solder paste made of? How to use solder paste in PCB assembly? Are there different types of solder paste? How do you store solder paste? Read on to know the answers to all of it and more.

What is Solder Paste?

Simply defined, solder paste is a combination of solder powder and a paste-like flux that gives it its name and texture. And now let's look at how flux solder paste came about and what solder paste comprises during modern times.

A Brief History

During the earlier days of PCBs, components were hand soldered directly onto the board. The process was good initially and went on for a while until demands for PCBs increased with changes in the electronic market.

To scale up production, engineers discarded the hand soldering method and went for wave soldering instead. The wave soldering process used molten solder to hold the components in place.

With electronic innovations speeding up, surface mount parts replaced the old thru-hole components of the PCB. Their absence of long leads demanded a new type of soldering. Liquid solder no longer proved useful. Thus, entered solder paste into the mix.

Solder Paste Composition

As outlined before, solder paste is a mixture of solder powder and flux paste. The solder powder is made of metal particles and the flux paste has a consistency similar to putty.

The job of the flux, much like putty, is to form a temporary adhesive until the surface mount components are securely soldered onto the printed circuit board. The flux also ensures that the solder powder remains free of contaminants when it is being administered to join the components to the board.

But what about the composition of the solder powder itself? Interestingly, it is not always the same. There are variations, also known as grades, depending on the requirement and type of the components. Continue to read further to know about these grades as we explain them in the next section.

Solder Paste Grades Explained

PCBs are made of different types of components. Hence, the characteristics of the solder paste used often vary. Some PCB assemblies might require a finer paste while some require coarser.

How fine or how coarse the solder paste should be, depends on the size of the metal balls that form the solder powder. The smallest size used in soldering PCBs is about 2 micrometers, although there could be a few particles (not more than 20%) in the mix that are smaller than that. This size is also termed Type 8.

As the particle size goes up, the grades go up simultaneously, from type 8 to type 7 to type 6 and so on. The highest grade, which is type 1, consists of at least 80% particles not larger than 150 micrometers. Here is the complete list of gradations.

GradeSize (in micrometers)

Type 1: 150-75

Type 2:75-45

Type 3:45-25

Type 4:38-20

Type 5:25-10

Type 6:15-5

Type 7:11-2

Type 8:8-2

What's more intriguing is that the solder particle size is not the only way that the solder paste is categorized. There are also several types of flux that give the powder the paste-like texture. Here they are.

Rosin-Based: Made of a natural extract from pine trees, this kind of flux can be cleaned from the board using solvents once the soldering is done.

Water-Soluble: Typically made of glycol and other organic components, water-soluble flux is easy to clean.

No-Clean: Made of resin and other solid residues, no-clean flux is preferred for its cost-effectiveness.

How is Solder Paste Applied to Printed Circuit Boards?

If you are someone who is just learning to build PCBs at home and want to know how to apply solder paste to it, the method is quite simple. All you need is a syringe and you can apply the paste to the individual components on the board.

Unfortunately, this method is too slow for large-scale manufacturing of PCBs. So, how is solder paste applied to PCBs in a factory setting? Well, there are two ways to go about it. Here they are.

Stencil Printing

In this method, first, a stencil is prepared according to the CAD drawing of a PCB design. The stencil includes all the minute apertures needed precisely as per the surface mount components of the PCB.

This stencil is placed on the circuit board that needs to be soldered. Next, the solder paste is applied to the stencil, typically using a squeegee. The stencil's apertures ensure that the appropriate amount of solder paste is applied to the board at precise locations.

Each soldered PCB is, of course, passed through an optical scanner to ensure that the soldering has been carried out to perfection. The stencil can be reused to solder the next set of PCBs of the same design.

Jet Printing

Stencil printing produces accurate results. But the time required to create the stencils can be huge. So, if a company is looking for rapid production of PCBs, jet printing could be the more viable option.

In the jet printing method, a slightly less viscous solder paste is used. Jet printers use this paste-like ink and eject tiny drops of it to solder the surface mount components to the circuit board. Using this method, engineers can control the amount of solder paste used for each soldering operation, something which is not possible when using stencils.

Solder Paste Storage Tips

Low-quality or degraded solder paste can be harmful to your PCB components. Not only would they degenerate quickly but will also harm your company's reputation if the soldered parts begin to fall off easily.

How do you avoid such incidents from occurring? A simple solution is to store the solder paste appropriately.

As solder powder is made of metals, it can easily oxidize when left in the open. Oxidation drastically reduces the quality of the solder balls and defeats the whole purpose of soldering. Hence, always ensure your solder paste is stored in air-tight containers.

The other factor you need to consider while storing solder paste is the storage temperature. If the environment is too hot, it could again lead to oxidation of the metals even when stored in air-tight containers. High heat also degrades the quality of the flux and then it is just not strong enough to hold the solder powder together.

To avoid such occurrences, store the solder paste in cooler temperatures. This does not mean that you stick it into a freezer. Freezing the solder paste can also degrade its quality. The optimum temperature to store solder paste is between 32 degrees F and 50 degrees F.

Solder Paste Vs Solder Mask

A PCB consists of components made of different materials, one of which is copper. When left in the open, copper tends to oxidize rapidly causing rust on the PCB. It can also attract dirt and other forms of contamination from the environment, resulting in an overall degradation of the circuit board.

To prevent such incidents, solder masks are applied. A solder mask is nothing but a thin layer of polymer applied on top of the copper portions of the PCB. As the name suggests, it masks the element and prevents it from oxidizing.

Another benefit of using solder masks is that it prevents accidental connectivity between two components on the board.

How does this happen? Well, during soldering, no matter how careful you are, there might appear small blobs of solder pastes on the circuit board at the wrong places. These blobs could allow the flow of electrons between components which, according to your design, should not have been connected at all.

This leads to the malfunctioning of the circuit board. It's a defect that can be prevented by using solder masks.

You can now imagine that the task of solder mask is quite the opposite of that of solder paste. While one aids in soldering, the other stops it.

Another key difference between the two is that while solder paste must be applied externally using stencils or jet printing, solder masks are just an additional layer on the PCB.

Takeaway

The process of soldering components on printed circuit boards has evolved as technology continued to change. From hand soldering through wave soldering to the use of solder pastes, things have come a long way.

Solder paste, which is a mix of small metallic balls and flux is now preferred for use in most large-scale PCB assemblies. The accuracy of stencil printers and the versatility of jet printers ensure that the finished PCB is durable and functions as per requirements.

As with anything else, the perfection of the soldering process depends on selecting the right grade of the solder paste and also storing the paste at optimum temperatures.

Of course, even with all the precision, any accidental connectivity occurring due to spillage of tiny blobs of solder paste can be avoided with ease by using a solder mask.

Previous article:2021 Detail Guide for PCB Ground Plane