General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

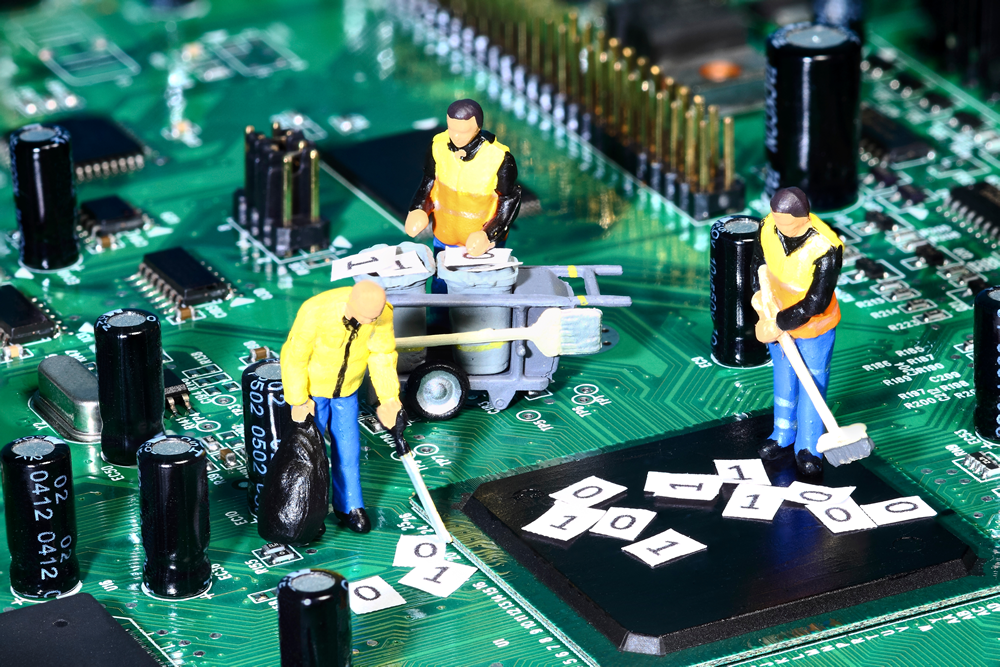

Useful Tips for PCB Cleaning

Simon / 2021-01-01

Contents [hide]

From the vehicles we drive to smartphones, medical equipment to TVs, printed circuit boards (PCBs) are present in almost all the electronics that we use today. With time, these circuit boards will accumulate dust, dirt and grime, leading to numerous issues. For instance, if your computer has slowed down significantly or it's overheating, there is a high chance that the circuit board is dirty. Fortunately, cleaning printed circuit boards is not as challenging as it appears. Read on to learn more about PCB cleaning, while if you are keen on cleaning flux from PCB, you need check this out.

How Does Printed Circuit Board Get Dirty

With daily use, the printed circuit boards present in electronics will be exposed to a wide range of contaminants, leading to speed and performance issues. Printed circuit boards get dirty due to two main reasons. First, the gaps present in the device, equipment or machine can let dirt and dust inside. Second, large appliances like computers and cars have cooling fans, which can draw in dirt, dust and other types of debris into the machine. Third, the wax used to coat some of the components can melt during high-temperature operations, thus becoming a magnet for dust and dirt. Identifying the type of contaminant and using the right cleaning method can help to alleviate the issue.

Why We Need to Clean Printed Circuit Boards?

As noted above, printed circuit boards are integral to the efficient and effective performance of our electronics. Therefore, if there is dirt and dust build-up on these circuit boards, there is a high chance that your electronic device, equipment or machine will malfunction.

For instance, if there is a heavy buildup of dirt and dust on your computer's motherboard, it may start slowing down or overheating. Therefore, cleaning that motherboard will not only help to remove the dirt and grime but it will also improve your computer's performance.

Second, dust, dirt, moisture and grime can lead to PCB corrosion, which will eventually shorten the machine's lifetime. So, cleaning PCBs regularly will help to arrest this corrosion and prevent premature damage.

Different Ways to Clean Printed Circuit Boards

There are various PCB cleaning methods that you can use to remove dirt, dust and grime from your electronics. The method you will use will depend on the type of contaminant, the type of board, the tools you have as well as the experience level. With that said, here are the most common PCB cleaning methods.

1. Compressed Air

Compressed is an effective PCB cleaner for removing dust and dirt lodged on printed circuit boards. When using compressed air to clean printed circuit boards, you should ensure that you first shut down the device and unplug all cables. Spraying compressed air on a plugged or powered device can lead to permanent damage. You may also be electrocuted in the process. Once you've shut down the device and unplugged all cables, you should then proceed to spray compressed air through the ventilation ports. If there is a thick layer of dust, you should open up your device and then spray the compressed air directly onto the circuit board. Spraying compressed air in short bursts will remove the lodged grime and give the PCB a clean look. The duration that you spray will depend on the amount of dirt and dust present on the circuit board.

2. Baking Soda

Also known as sodium bicarbonate, baking soda is a powerful PCB cleaning solution for removing grime and corrosion while posing minimal damage risk to the board. Baking soda comes with mild abrasive and alkalinity features, which can help to remove corrosion residue that may prove impossible to remove using an ordinary brush. It will dissolve the residue while neutralizing acidic corrosive agents. Just like when you are using compressed air, you should first detach the device from all cables. Also, ensure you pull out all chips that may have been inserted into the board before cleaning. After detaching all the cables and chips, you should then mix baking soda and water, and then stir it until you have a runny paste. You should then use a cotton swab to apply the paste gently to all the corroded areas of the circuit board. Allow the paste to sit on the circuit board for approximately 24 hours. After the 24-hour duration has lapsed, you should then wipe off the baking soda paste using isopropyl alcohol.

3. Isopropyl Alcohol

Isopropyl alcohol is also a great PCB cleaning solution, especially when you are dealing with sticky grime. Ensure you use isopropyl alcohol whose concentration is at least 90% to 100% alcohol. Once you've acquired the alcohol, you should then apply it on a cotton swab and use it to wipe your printed circuit board. Ensure you squeeze the cotton swab to remove excess moisture - which may cause damage. Also, make sure you wear personal protective equipment such as goggles and gloves when handling isopropyl alcohol. You should also ensure you are using it in a well-ventilated area since isopropyl alcohol can produce toxic fumes.

4. Distilled Water

Unlike other circuit board cleaners like baking soda and isopropyl alcohol, distilled water doesn't contain ions. Therefore, it will not damage or degrade your electronic devices when you use it to clean the circuit boards. It's important to note that distilled water can be contaminated by dirt quickly and easily, thus rendering it useless. So, make sure you keep it properly sealed whenever you are not using it to minimize contamination.

5. Household Cleaners

If you've tried all the above PCB cleaning methods and none seems to work, then you can try to remove the dirt using household cleaners. Apart from removing the dirt and grime, most phosphate-free household cleaners can also help to protect printed circuit boards from corrosion.

As you can see, you have numerous methods that you can use to clean printed circuit boards. In case one method doesn't work, you should then try another one until you find a solution that works best for your situation.

Tools Used to Clean a Printed Circuit Board

When cleaning circuit boards at home, you will need several tools to get the job done effectively and efficiently. The tools you will use will depend on the cleaning method that you've chosen.

A brush and lint-free towels are a must-have when it comes to PCB cleaning. Ensure you choose a brush with soft bristles. Also, it should be small enough so that you can comfortably reach even the tight spaces. And a toothbrush will be ideal in this situation. Artists' paintbrushes can also produce similar results.

As for the lint-free towels, you need them when applying the baking soda paste or isopropyl alcohol. Lint-free towels don't shed debris, and that's why they are preferred when it comes to delicate cleaning tasks. Regardless of the tool or method that you are using, you should always ensure that the device is completely unplugged from all cables. Also, make sure you give the circuit boards ample time for drying before you re-assemble the device. Re-assembling the device and connecting it to a power source when it's not dried completely can lead to short-circuiting or even electrocution.

An oven, table lamp or blow dryer can also come in handy during PCB cleaning. They will speed up the drying process, especially when you've used a wet PCB cleaning solution. Drying off your circuit boards fast will help to prevent damage.

Ultrasonic PCB Cleaning

Ultrasonic PCB cleaning is arguably one of the most efficient means of removing dirt, dust, solder paste and flux that may be lodged on the boards. In short, this PCB cleaning method can remove almost any form of dirt and grime, including tenacious residues. And during the cleaning process, the ultrasonic cleaner will not damage even the delicate boards.

When you immerse the printed circuit board in a PCB ultrasonic cleaner, the cleaning process will commence immediately after the liquid comes into contact with the board. And since the cleaning liquid will reach even the smallest cavities and crevices, it will remove all the dirt and grime that you can't remove manually.

PCB ultrasonic cleaners use cavitation during the cleaning process. The higher the ultrasonic frequency, the smaller the size of the cavitation bubbles. So, for cleaning smaller openings or delicate parts, then you should opt for higher ultrasonic frequencies. On the other hand, if you are removing heavy contamination from your printed circuit boards, then you should choose lower ultrasonic frequencies.

However, it's important to note that this cleaning method should only be used on empty circuit boards. Since it involves using water, ultrasonic PCB cleaning can loosen connections or damage components present on the board. And that's why you should ensure that the board doesn't have any components. Furthermore, you should always follow manufacturers' instructions when using PCB ultrasonic cleaners.

Final Thoughts For PCB Cleaning

Without a doubt, dirty circuit boards can lead to a wide range of issues for your devices. And if the dirt, dust, grime or corrosion is left to accumulate on the circuit boards, it may lead to premature device failure. The good news is, you can easily clean printed circuit boards on your own, as long as you have the right tools and PCB manufactureing supplies.