General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

PCB Prototyping 101: The Fast Track to Market

PCBA Store / 2026-01-15

Contents [hide]

In today’s quick-moving electronics field, delivering fresh products to buyers before rivals do stays a main factor for success. Getting to market fast matters a lot. At the same time, keeping strong quality levels remains very important. PCB prototyping helps turn ideas into working hardware in a short time. It makes complete testing and checking possible before large production starts. This method shortens development steps. It cuts down risks. It also improves costs while still keeping things dependable. PCBA Store, as a direct manufacturer and one-stop supplier for PCB fabrication and assembly, helps with fast prototyping through modern skills and strong benefits.

What are PCB Prototypes?

A PCB prototype is the first version of a printed circuit board made for checking and improving. It works as an early sample. This sample checks how the circuit runs, where parts sit, and if the whole idea works well before spending a lot on full production. Prototypes help spot design mistakes, operation problems, and build issues right at the start.

Prototypes come in different types based on their goal and how complete they are:

· Proof-of-Concept (POC) Prototype: This simple version checks basic ideas and main technologies. It shows if the plan can work and points out big problems without adding every feature.

· Functional Prototype: This better version includes important features. It acts much like the final product in use. It allows careful testing of performance, checks how users work with it, and supports ongoing changes.

· Pre-Production Prototype: This is the most polished step. It matches the final item in shape, size, and action. It confirms assembly steps, ease of building, and rule-following. It acts as the final check before big manufacturing runs.

Moving step by step through these levels brings steady improvement. Input from each round guides changes. This leads to a solid and trustworthy final design that meets performance and dependability goals.

The Prototyping Process

The road from first idea to finished PCB prototype uses clear steps. These steps help make sure everything is correct and works well:

1. Schematic Design: It all starts with drawing a schematic diagram. This plan shows electrical links, part details, and how the circuit acts. It directs every later step.

2. Layout: The schematic turns into the real board design. Parts get placed in smart spots. Traces get routed to keep signals clean, power use low, and building easy. Modern software improves things like impedance control and heat handling.

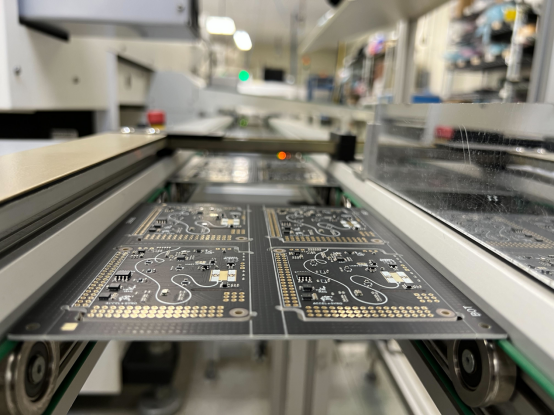

3. Fabrication: The design moves to actual making. Copper-covered boards go through etching to create traces and pads. Then drilling makes vias and through-holes. Surface finishes and solder masks get added to guard the board and get it ready.

4. Assembly: Parts go onto the made board. This uses methods like SMT for surface-mount items and THT for through-hole ones. Ways include automatic pick-and-place, reflow soldering, and careful hand work for tricky or small runs.

5. Testing: Strict checks prove it works right. These include looking closely by eye, AOI, X-ray for hidden spots, ICT, functional testing, and stress tests in different settings to confirm it holds up.

Good teamwork between design groups and manufacturing partners during all these steps speeds up changes and fits in needed fixes smoothly.

Choosing the Right Prototyping Partner

Picking the best PCB prototyping partner affects how well a project turns out. Important points go past just low prices. They cover trust and fit with project goals:

· Experience and Expertise: Partners with wide knowledge in many PCB kinds—from basic single-layer to complex multilayer, HDI, flex, and rigid-flex—show skill with industry rules and tough needs.

· Technical Capabilities: Look at machines for exact making, fast assembly lines (e.g., Panasonic and Yamaha mounters), and check tools (SPI, AOI, X-ray). Backing for materials like FR-4, Rogers, polyimide, and heavy copper, plus options like impedance control and buried vias, matters a great deal.

· Turnaround Time: Quick shipping is very key. Fast choices give 24-hour turnaround for easy 2-layer boards and 1-5 days for harder prototypes or assemblies. This fits tight project plans.

· Cost-Effectiveness: Match quality and speed with good prices. Direct manufacturers cut out middle steps. They give no MOQ, no setup fees, and extra benefits like free passive components in turnkey orders.

· Scalability: The power to move easily from prototypes to medium or high-volume production keeps things smooth without new checks or redesigns.

A partner that offers one-stop services for fabrication, assembly, component sourcing, and testing makes work flow better and keeps things steady.

Why PCB Prototyping Matters

PCB prototyping brings smart gains that go past simple checking:

· Risk Mitigation: Finding problems early stops costly fixes in big production. It avoids hold-ups and extra work.

· Design Optimization: Repeated testing improves layouts, part picks, and results. This creates more effective and long-lasting items.

· Faster Time-to-Market: Fast rounds cut development time. They allow strong market entry and quick answers to customer wants.

· Improved Product Quality: Testing in real settings finds issues with function, dependability, and rules. This leads to better final items.

· Reduced Costs: Money spent early on prototypes saves bigger losses from build mistakes, returns, or full redesigns.

In a field where new ideas come faster and faster, good prototyping sets projects up to win.

Frequently Asked Questions (FAQ)

What is the typical turnaround time for PCB prototypes?

Turnaround changes with complexity: 24 hours for basic 2-layer boards, 2-5 days for multilayer or advanced prototypes, and 1-10 days for PCB assembly, with express options available.

What file formats are required for quoting and production?

Gerber files (for PCB), BOM (in Excel/CSV), and assembly drawings (PDF) support instant online quotes and seamless manufacturing.

Do minimum order quantities apply?

No MOQ exists for prototypes or low-volume production, making it suitable for single units to small batches.

What testing methods ensure quality?

Processes include AOI, X-ray inspection, ICT, functional testing, and adherence to IPC-A-610 standards, achieving over 99.5% qualification rates.

What industries benefit from these services?

Robotics, medical devices, automotive, communications, industrial equipment, and consumer electronics commonly utilize these capabilities.

Partner with PCBA Store for Your PCB Needs

PCBA Store operates as a direct manufacturer, supplier, and factory specializing in PCB prototyping, fabrication, and assembly. With facilities in Shenzhen, the company provides one-stop solutions including rapid prototyping (as fast as 24 hours), full turnkey PCBA, component sourcing, and advanced capabilities up to 64 layers, HDI, flex/rigid-flex, and heavy copper. ISO9001-certified processes, online instant quoting, 24/7 support, and a commitment to quality, speed, and affordability make PCBA Store a reliable partner for accelerating projects from concept to market.

Contact the team today via the online quote system at https://www.pcbastore.com/online_quote.html or email svc@pcbastore.com to discuss requirements and receive a tailored proposal. Start the journey toward efficient, high-quality electronics manufacturing now.

Previous article:Rigid-Flex PCB Manufacturing Process and Applications