General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

Rigid-Flex PCB Manufacturing Process and Applications

PCBA Store / 2026-01-15

Contents [hide]

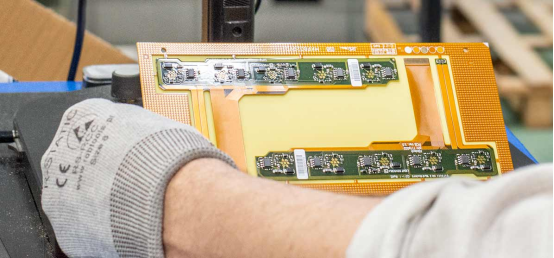

Rigid-flex PCBs, also called rigid-flex circuit boards or semi-flex PCBs, combine rigid FR4 sections with flexible polyimide layers into one connected structure. This kind of design lets certain areas stay bendable. At the same time, other parts give strong mechanical support and places to mount components. Circuits keep steady connections all across the board. That removes the need for extra connectors, cables, or jacks. Those items often take up precious space in small assemblies.

This article looks at rigid-flex PCBs, their full manufacturing process, top one-stop manufacturers, and main applications in today's flexible electronics.

Part 1: What is a Rigid-Flex PCB

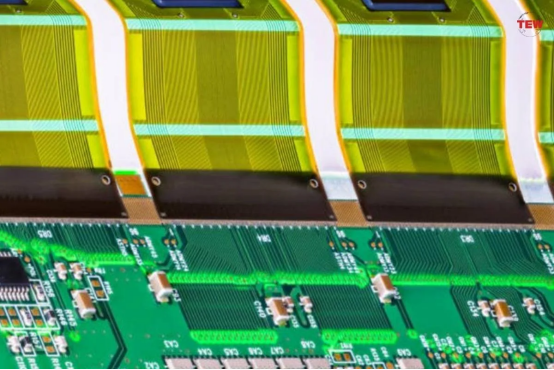

A rigid-flex PCB joins flexible PCB layers in the center with rigid FR4 layers laminated on the top and/or bottom. The flexible core usually uses polyimide. It covers the whole board size and allows bending in chosen zones. Rigid sections come from FR4 laminates. They bring extra structural strength for placing components and giving support.

Engineers created rigid-flex technology to solve tough problems in aerospace uses. Those needs included high-density interconnects, flexibility, very limited space, lightweight build, and strong mechanical reliability. Rigid-flex PCBs fix these problems well. They provide smooth joining of rigid and flexible parts without any extra interconnect hardware.

Now, rigid-flex PCBs go far beyond aerospace. They appear in medical devices, consumer electronics, industrial equipment, telecommunications, automotive systems, defense, and scientific instruments. In these fields, tight space limits and changing conditions call for better solutions.

Part 2: Rigid-Flex PCB Manufacturing Process

Rigid-flex PCB fabrication needs careful handling. That is because it mixes different materials. Precise alignment is also required during lamination and via creation. Manufacturers build the flexible core first. Then they laminate rigid layers onto it. The exact steps change depending on layer count, HDI needs, and design difficulty.

Here is the usual manufacturing sequence for rigid-flex PCBs.

Step 1. Prepare the overlay, prepreg, flexible laminates, and rigid PCB laminates

Materials such as coverlay (for flex protection), prepreg (PP), flexible copper-clad laminates (FCCL), and rigid FR4 laminates get cut to the right size. In rigid areas that cover exposed flex zones, copper foil is removed in selected spots. This step helps make later removal easier.

Step 2. Drill on coverlay, PP, rigid laminates, and flex laminates

Positioning holes are drilled by machine for good alignment. For HDI designs, laser drilling makes microvias. Through-holes and vias connect layers between rigid and flex regions.

Step 3. Pre-process overlay, PP, and rigid laminates

Extra rigid areas above future exposed flex sections go through pre-processing. This includes controlled-depth routing or window openings. Those steps allow clean removal after lamination.

Step 4. Circuit generation on the flex PCB

For single-layer flex cores, circuit patterns move to the laminate. Then rolled annealed copper gets etched away. Multi-layer flex cores (2–6 layers) use step-by-step lamination of PI and copper layers. Circuit patterns form on each copper surface.

Step 5. Laminate coverlay on flex PCB layers

After circuits form and AOI inspection finishes, coverlay laminates onto the flex core. It protects traces and gives insulation.

Step 6. Laminate the rigid laminates on the flex section

Copper and prepreg layers alternate and laminate onto the flex core. This builds the rigid sections. Good alignment keeps continuity between rigid and flex circuits.

Step 7. Drill plating-through holes and generate circuits on rigid layers

PTH drilling happens across the whole panel. For 1–2 rigid layers, circuits form right on the outer layers. For 4+ rigid layers, internal layers get circuit patterns first. Then more lamination follows, along with PTH drilling and outer-layer patterning.

Step 8. AOI, solder mask, surface finish, and silkscreen

Final AOI checks circuit quality. Solder mask goes on (usually green, but other colors work too). Next come surface finishes (ENIG, HASL, OSP, etc.) and silkscreen legend printing.

Step 9. Remove the extra rigid areas on the to-be-exposed flex PCB areas

Laser cutting or depth-controlled routing takes away extra rigid material. This exposes the flex coverlay so it can bend. Boards separate from production panels. Then electrical testing follows. It includes power-on self-test and four-terminal sensing for high-reliability uses (defense, medical, automotive, aerospace).

Advanced types include HDI rigid-flex, heavy copper in rigid sections, and component mounting on exposed flex areas.

Part 3: One-Stop Rigid-Flex PCB Manufacturer

PCBA Store operates as a direct manufacturer and supplier in Shenzhen, China. It provides complete rigid-flex PCB solutions. These cover design support, fabrication, component sourcing, assembly, and box-build services. With more than 16 years of experience, the facility manages prototypes up to mass production. There is no minimum order quantity.

PCBA Store's rigid-flex PCB capabilities include:

· Flex section layers: Up to 6 (mass production); 10 (samples)

· Total rigid-flex layers: Up to 22 (mass production); 24 (samples)

· Minimum rigid-flex PCB size: Smallest feasible (down to prototypes)

· Maximum rigid-flex PCB size: Aligned with rigid capabilities (up to 1250mm × 570mm for multilayer)

· Rigid-flex PCB thickness: Starting from 0.26mm for 4-layer configurations

· Minimum trace width/space: 65/65µm inner (mass); finer for samples

· Through-hole size tolerance: Mechanical 0.1mm min; laser 0.1mm min

· Flex copper thickness: 12µm min (mass)

· Rigid copper thickness: Up to 6oz (mass); higher for samples

· Minimum mechanical via aperture: 0.1mm

· Minimum laser blind via aperture: 0.1mm

· Structures: Symmetric/asymmetric, bookbinder, air-gap, fly-tail, HDI (2+C+2)

Additional features include impedance control (±10%), high-frequency materials (Rogers, etc.), and RoHS-compliant processes. Online instant quoting, free DFM reviews, and quick turnarounds (24-hour for select prototypes) help projects run smoothly. PCBA Store also handles assembly of rigid-flex boards. It uses SMT, THT, mixed technology, AOI, X-ray, and functional testing.

Part 4: Rigid-Flex PCB Applications in Flexible Electronics

Rigid-flex PCBs improve flexible electronics. They mix bendable areas with solid support for components and connections.

Applications include:

1. Rigid-flex PCBs for smart wearable devices Rigid-flex boards allow small, comfortable designs in VR headsets, smartwatches, wireless earbuds, fitness trackers, and smart clothing. The boards fold to match curved enclosures.

2. Rigid-flex PCBs for automotive electronics In vehicles, rigid-flex PCBs handle vibration, extreme temperatures, and tight spaces. They work well in control modules, sensors, ADAS systems, infotainment, and brake electronics.

3. Rigid-flex PCBs for communication electronics Mobile phones, laptops, foldable displays, and cameras use rigid-flex in hinge areas, screen connections, and high-density signal routing.

4. Rigid-flex PCBs for medical, defense, aerospace, and industrial electronics Devices like wearable monitors, surgical tools, satellite rotation mechanisms, industrial controllers, and defense systems gain from reliable bending and strong build.

Conclusion

Rigid-flex PCBs blend rigid and flexible technologies. They create compact, dependable interconnects in tough settings. Exact steps like laser drilling, controlled lamination, and selective removal add to the fabrication challenge. PCBA Store, as a leading one-stop manufacturer, supplier, and factory, supplies high-quality rigid-flex solutions. It offers full capabilities, fast prototyping, assembly integration, and cost-effective production.

FAQ

What is the main difference between rigid-flex PCBs and separate rigid and flex boards connected by connectors?

Rigid-flex PCBs create one single integrated board with continuous circuits. This cuts down interconnect failures, space usage, and assembly steps compared to separate boards joined by connectors.

How many layers can rigid-flex PCBs support?

PCBA Store supports up to 22 layers in mass production and 24 layers for samples, with flex sections up to 6–10 layers.

What industries benefit most from rigid-flex PCBs?

Wearables, automotive, medical, aerospace, defense, communication, and industrial applications gain from space savings, reliability in dynamic conditions, and reduced weight.

Does PCBA Store offer assembly for rigid-flex PCBs?

Yes, PCBA Store provides full PCB assembly including SMT, THT, mixed technology, component sourcing, AOI, X-ray, and functional testing on rigid-flex boards.

What file formats are required for rigid-flex PCB quoting?

Gerber files, BOM (for assembly), and specifications (layers, materials, surface finish) enable instant online quotes; complex designs can be emailed for review.

Partner with PCBA Store for Rigid-Flex PCB Needs

PCBA Store serves as a direct manufacturer, supplier, and factory specializing in rigid-flex PCB fabrication and assembly. Businesses seeking reliable, cost-effective rigid-flex solutions benefit from factory-direct pricing, no MOQ, free DFM reviews, rapid prototyping, and one-stop services covering design support to box-build.

Upload Gerber files and requirements for an instant quote today. Contact the team at svc@pcbastore.com or visit the online quote system at https://www.pcbastore.com/online_quote.html to start projects efficiently. Experience seamless production with PCBA Store's proven expertise in rigid-flex technology.

Previous article:Turnkey PCB Assembly Explained Full vs Partial Process And Benefits