General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

Turn Key PCB Assembly: Streamlining Your Manufacturing Process

PCBA Store / 2026-02-26

Contents [hide]

Turn Key PCB Assembly: Streamlining Your Manufacturing Process

In the fast-paced electronics field today, Turnkey PCB Assembly offers a complete, practical option. It covers all parts of making printed circuit boards, from early design to the finished, checked product. This single-package method makes the PCB Manufacturing path easier. Businesses can hand off tough tasks. They gain quicker time to market and better results. As a Turnkey PCBA Supplier China in Shenzhen, we at PCBA Store deliver smooth One-Stop PCB Assembly services. We blend our skills in making, finding parts, putting together, and checking. All under one place for the best watch and outcomes.

What is Turn Key PCB Assembly?

Turnkey PCB Assembly is a total service. One provider takes charge of the whole build cycle for printed circuit board assembly (PCBA). This covers PCB design check or setup if required. It also includes part buying, blank board making, SMT and THT putting together, strict checks, and even box-build joining. This fits firms short on inner tools or know-how. The setup skips the need to line up many sellers.

In our One-Stop PCBA Assembly flow, clients just send Gerber files, BOM, and details. We manage the rest. We source steady parts. Often, passive ones come free from our stock. Then, we send ready-to-use boards. This help works for test models, small runs from 10 pieces, and big builds up to millions. Our modern spots in Shenzhen handle tight-pitch parts down to 01005 and 0.4mm pitch. We work with stiff, bendy, and stiff-bendy boards. Features include HDI, impedance watch, and thick copper.

By picking a Turnkey Electronics Manufacturing ally like us, companies dodge traps. These are supply line waits or quality ups and downs. Our joint method brings clearer tracking, lower dangers, and is fit with rules like IPC-A-610F and RoHS.

Benefits of Turn Key PCB Assembly

Turnkey PCB Assembly brings real gains. It serves as a top pick for new companies, small to medium ones, and established firms.

Cost Savings

Handing off to a Turnkey PCBA Supplier China cuts costs a lot. We use big-buy power for parts. We skip ship and storage fees for clients. We give maker-direct prices with no MOQ, no start fees, or NRE costs. Passive parts often come free in turnkey jobs. Fair China-based making keeps prices low. They are a small part of Western choices. Yet, quality stays high.

Time Savings

Quickness matters in electronics growth. Our simple One-Stop PCB Assembly shortens wait times a great deal. Prototypes take 3-5 days. Fast assembly runs in 8-48 hours. Regular builds need 1-10 days. By doing all steps inside, we skip seller pass-offs. Those cause waits. This lets for faster changes and speedier market push.

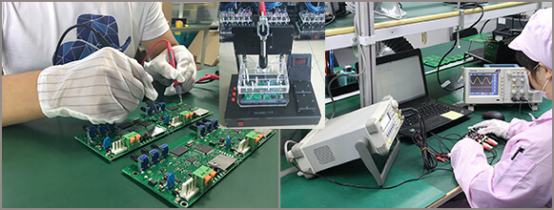

Quality Control

Top quality comes from a full watch. We put strong checks at each point. These include solder paste inspection (SPI), automated optical inspection (AOI), X-ray for hidden joins in BGAs/QFNs, in-circuit testing (ICT), and functional circuit testing (FCT). Our pass rate goes over 99.5%. Complaint rates sit under 0.2%. Papers and close follow of IPC Class 2-3 rules make sure of steady, flaw-free goods.

Reduced Risk of Errors and Defects

Skilled groups spot problems soon. They use design checks and process holds. This cuts fix work. Our trained engineers and workers find likely issues. They act before these hit-making.

Focus on Core Competencies

By passing on PCB making, firms shift tools to new ideas, selling, and market work. This helps non-electronics experts the most. They gain from our special skills.

Scalability and Flexibility

From fast test models to large runs, our help grows easy. We back mixed-tech puts (SMT/THT), conformal cover, burn-in setup, and box-build for full Turnkey Electronics Manufacturing.

Turn Key PCB Assembly Process

The Turnkey PCB Assembly flow at our site uses a planned, effective pattern.

Design and Engineering

We start with a full look at your files. We give free engineering aid and tips for making ease. This makes sure designs fit build rules right away.

Procurement of Components

Our world supply line finds good parts fast. Sure, sellers and inner stock for passives make this step smooth. We handle a full BOM in turnkey work.

PCB Fabrication

With modern gear, we make blank boards up to 40 layers. Prototypes reach 64. We support FR-4, high-speed stuff, HDI, and stiff-bendy. Wait times go from 24 hours fast to usual 2-4 weeks.

Assembly

Exact SMT placing uses Yamaha and Panasonic machines. They fit tight-pitch and dense boards. THT and mixed putting follow. Reflow soldering is set for lead-free or leaded ways.

Testing

Full proof includes AOI, X-ray, ICT, FCT by your steps, and sight/final looks. This makes sure of work and steadiness before send-off.

Choosing a Turn Key PCB Assembly Provider

Picking the best ally is key for job win.

Experience and Expertise

Seek clear past wins in like projects. With 16+ years in PCB making and 8+ in putting, our Shenzhen site shines in varied fields. These cover medical, telecom, and user electronics.

Quality Control Measures

Choose helpers with many-step checks and high pass rates. Our ISO9001-fit setup, AOI/X-ray/ICT/FCT, and <0.2% complaint rate bring great steadiness.

Customer Support

Good talk and quick reply count. We give 24/7 aid, fast online prices, order follow-up, live chat, and after-sell guard. This covers money back or a free fix for wrongs.

Conclusion

Turnkey PCB Assembly gives a smart, money-saving path to hand off PCB Manufacturing. It offers a real one-stop fix that runs from design aid to end delivery. Teaming with a solid Turnkey PCBA Supplier China like us cuts seller mix. It lowers costs, speeds times, and keeps high quality. This way helps firms make new things. We take care of the hard parts in One-Stop PCBA Assembly and Turnkey Electronics Manufacturing.

As a committed maker, seller, and site in Shenzhen, we at PCBA Store promise top Turnkey PCB Assembly made for your wants. With our strong tools, quick turns, and client-first way, we aid in bringing your electronics ideas to reality. Reach us now for a fast online price. See how our One-Stop PCB Assembly can make your next job smoother.

Frequently Asked Questions

What is the difference between full turnkey and partial turnkey PCB assembly?

Full turnkey includes everything—PCB fab, component sourcing, assembly, and testing—while partial allows you to supply some parts.

How does Turnkey PCB Assembly save costs in PCB Manufacturing?

It leverages bulk sourcing, eliminates multiple vendor fees, and offers direct manufacturer pricing with free passives and no hidden charges.

What testing is included in One-Stop PCBA Assembly?

Standard tests cover AOI, X-ray, ICT, FCT, and visual inspection to ensure high reliability and compliance.

Can Turnkey Electronics Manufacturing handle prototypes and mass production?

Yes, our services scale from 1-10 piece prototypes to high-volume runs up to 1 million, with quick-turn options.

Why choose a Turnkey PCBA Supplier China like PCBA Store?

We provide integrated control for better quality and lead times, competitive pricing, no MOQ, and proven expertise in complex assemblies.

Ready to Streamline Your PCB Projects with Turnkey Solutions?

As a top maker, seller, and site focused on Turnkey PCB Assembly, we at PCBA Store give full One-Stop PCBA Assembly to fit your business needs. From fast prices and quick test models to big-scale making with strong quality, our Shenzhen group makes sure of steady, low-cost results. Get in touch today through our online price tool or email. Start your job and feel the perks of teaming with a trusted Turnkey PCBA Supplier China.