General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

How to Tell If A Circuit Board Is Bad

Simon / 2021-04-12

Contents [hide]

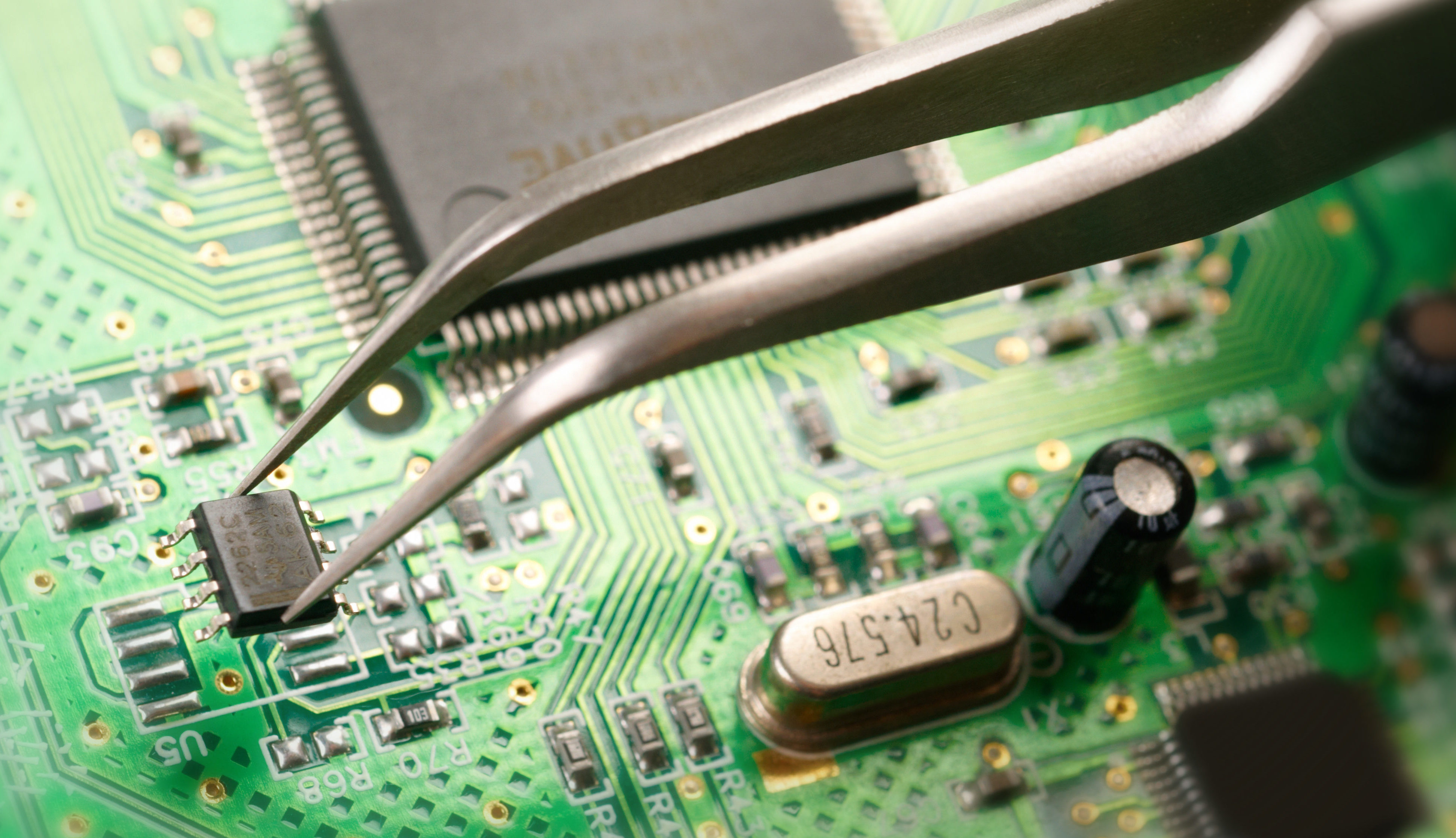

Printed circuit boards provide the foundation of many electronic devices and are the core of technology around the world. Printed circuit boards, commonly referred to as PCBs, feature thin boards that are made from insulated material. They consist of metal coating on both or one side and electrical pathways engraved into them make it possible for electricity to be transmitted through different parts that have been connected to the board.

We deal with various aspects of circuit boards while helping customers identify the issues that affect their boards. Whether you require assistance with a handful or numerous circuit boards, we can accomplish the task and ensure that you get a clear diagnosis for your circuit board. If you need help with circuit board testing or a bad circuit board, we are available to check and verify the problem.

Things We Need to Check If A PCB Is Bad

Printed circuit boards can break down and become defective in different ways and this may result in the total or partial failure of various electronics. PCB damage usually occurs when the board is not handled properly, some times you could just repair PCB trace damage yourself.

As an essential feature of several electronic devices, the PCB plays a major role in their functionality. This is why it is important to be aware of the signs of a bad circuit board and when replacements are necessary.

Schematic or Service Manual

All types of electronic equipment, including PCBs can experience a wide range of problems. Troubleshooting involves identifying and eliminating problems in order for the equipment to work normally.

Generally, PCBs are designed and produced to work without any issues within certain limits during their lifecycle. But there are times when the user's expectations are not met and this creates the need to know how to tell if a circuit board is bad.

Troubleshooting consists of isolating and fixing the cause of a malfunctioning circuit board. The process is based on systematically finding the problem when the board does not work as expected or does not work at all. The basics of finding and rectifying the reason for PCB damage include looking for possible faults and circuit board testing.

Signal Generator

The signal generator is an essential aspect of the troubleshooting process. It serves the purpose of providing proven test conditions to assess the performance of the circuit board design and to replace the missing signals while repairing the system.

Oscilloscope

Oscilloscopes are instruments that are usually used to facilitate the display and evaluation of electronic signal waveforms. This is a vital tool that lets you observe varying electric signals as time goes on, which is important for detecting why your circuit is not working properly. An oscilloscope displays the information you need during circuit board testing.

Checking if a PCB is bad

Instructions

1. If electronic components have been installed, test the board while the power is on.

2. Turn off the source of power to the circuit before looking at the board. You also need to remove any existing electrical components by using wire cutters to clip the connection wires and pull them away from the circuit board. Pull out the things that do not need to be clipped by unplugging them.

3. Examine the circuit board and search for signs such as crushed components, bulges, damaged wires, cracks, misplaced or extra solder, burn marks and scratches that indicate that the board is either bad or requires replacement and professional assistance.

4. A scratch creates the risk of exposing and damaging the connections under the lamination. Misplaced solders can lead to a short circuit and disrupt the other connections. Avoid further tests when you see these types of signs because they can be hazardous. You can conclude that any damaged parts are defective.

5. Connect the circuit board to its regular power source and turn it on. Use an oscilloscope to test the voltage of every connection within the circuit board schematic. This is done by applying probes to the ends of each connection with the appropriate voltage, which makes it easier to isolate the issue faster.

6. Note down the results of all the connections and make comparisons based on the information from the circuit board schematic. If the connections do not conduct the specified voltage, this means that you are dealing with a bad circuit board.

Four Common Causes of PCB Failure

As previously discussed, printed circuit boards are crucial components in a variety of electronics that range from airplanes to medical equipment. This is why it is important to understand the causes of circuit board failure and how they can be avoided. Things such as age and weather can ruin a circuit board, leading to sporadic or total power failure. Usually, the common reasons for a malfunctioning PCB arise from the following:

Burnt Components

Burnt components are a type of defect that usually happens when PCBs are exposed to high temperatures. The likelihood of a burnt component rises significantly when the space surrounding it is not enough. However, shape and size also affect the amount of heat that a component can handle before it burns up.

The component may be anything, ranging from a microprocessor to a capacitor. You may need to replace it completely if fails to work. Due to overheating, such components can contribute to operational problems and a device failing to power on.

Poorly Manufactured Components

Power failure and improperly placed components are some of the things that may go wrong during the designing and manufacturing stages of production. Issues include soldering problems, chemical leakage and barrier breakage. There are numerous requirements and variables that need to be considered in order to minimize the risk of errors. These include human error, cleanliness and the room's environment.

Human error during manufacturing and assembling can also lead to PCB failure. This consists of different factors like poor connectivity between the layers of the board, poor soldering and components that have not been installed properly.

Signs of a poorly manufactured board include a bad solder, connection issues and loose components. Automating the manufacturing process helps to reduce the possibility of issues that may lead to circuit board failure.

Environmental Factors

The environment within the room in terms of aspects such as humidity may have an impact on the way the solders and components react while being assembled. This is why it is necessary to regulate the environmental conditions. Cleanliness is another important factor because any form of contamination can disrupt the PCBs.

Power surges or overloads, impact of accidental falls and exposure to moisture, dust and heat can cause a PCB to malfunction. There are different environmental factors that affect how a PCB performs. One of the most damaging causes is the circuit board being exposed to harsh situations and elements that can disrupt its functionality.

Other causes included submersion in water, electrical fires and lightning. While these issues are common culprits of circuit board breakdowns, even the most perfectly crafted board would find it difficult to overcome these factors. Variables like debris and dirt will corrode a board and cause it to degenerate over time. Extreme heat also plays a role in reducing the lifespan of a circuit board.

Age

With time, some of the components of a circuit board may start to fail. As a PCB gets older, it is vulnerable to breaking down. The components start to malfunction once they reach the end of their lifespan and this situation can be addressed through repair or a new replacement.

Luckily, several issues that occur due to age can be fixed affordably by replacing faulty parts with new ones as a sustainable and economic option. PCB failure that arises as a result of age is inevitable but the cost of getting replacements can be regulated when new parts are used rather than assembling a new circuit board.

Circuit boards fail for various reasons, even before the consumers receive them. Being aware of the causes of failure makes it easier to avoid failures in the future and benefit from effective circuit board testing. Many PCB failure concerns can be dealt with through repairs and reworking the system after performing an in-depth inspection and evaluation. While defects like a burnt component can be visually inspected, you would need an experienced technician to diagnose more complex issues.

Conclusion

Many people are not aware that the devices and electronics they own consist of numerous internal components that work together to facilitate the necessary features and functionality of the things they use. Inside devices such as mobile phones, there are many pieces that connect the required components. A printed circuit board is among these vital pieces and it is the foundation of several electronics.

Without a PCB, various devices would not be able to function at all. In case of a malfunction or failure, some major issues can arise. Over time, circuit boards may experience damaging effects that can diminish their overall functionality and performance. Things like age, humidity and weather affect the condition of a circuit board.

Fortunately, it is possible to rework or repair boards and make them brand new again. Before a board is reconditioned or repaired, the first step is to understand and determine what went wrong. Knowing how to tell if a circuit board is bad involves identifying the problems and the ways they can be solved.