General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

What are the Advantages of Surface Mount Technology in PCBA?

PCBA Store / 2026-02-12

Contents [hide]

What are the Advantages of Surface Mount Technology in PCBA?

In the quick-moving field of electronics, surface mount technology (SMT) has changed PCBA manufacturing. It makes printed circuit board assemblies smaller, more effective, and cheaper. SMT serves as an option to old through-hole ways. It lets people put parts right on the PCB surface. This simplifies the PCBA process. It also boosts general performance. Such a change is now vital in today's PCBA manufacture. There, automatic systems and exact work are crucial for matching tough industry rules. At PCBA Store, we focus on giving top-notch SMT options. We do this within our full PCBA manufacturing services.

What is Surface Mount Technology?

Surface mount technology means the way to fix electronic parts directly onto the surface of a printed circuit board. It skips drilling holes and putting in leads. SMT came about in the 1970s and 1980s. It arose to fix the problems of through-hole (TH) technology. That old method used ready-made leads. Those often led to assembly hold-ups and higher expenses. On the other hand, SMT parts like resistors, capacitors, and integrated circuits go on pads or lands on the PCB surface. Then, soldering holds them in place.

The PCBA process with SMT usually has a few main steps. First, apply solder paste with a stencil. Next, use automated PCBA machines for component placement. These include pick-and-place systems. After that, do reflow soldering in an oven. Finally, check everything. This automatic setup cuts down on handwork. As a result, it suits large-scale production well.

Through-hole parts need leads that go through the board. SMT skips that entirely. Therefore, it allows tighter setups and boards with many layers. This tech backs different package styles. For example, it handles chip-scale packages (CSP) and ball grid arrays (BGA). These are key for small gadgets like smartphones and wearables. In PCBA manufacturing, SMT speeds up the assembly line. Plus, it fits well with quality check tools. Such tools include PCBA test fixtures for in-circuit testing (ICT) and functional circuit testing (FCT). All this makes sure things are dependable before shipping.

Benefits of Surface Mount Technology in Design

SMT provides many pluses that make it the top pick in PCBA manufacture. These perks range from design freedom to making production smoother. They help engineers build fresh products. These meet current needs.

Maximum Flexibility When Building PCBs

A key plus of SMT is how flexible it is for PCB design. There are no limits on through-hole leads. So, designers can put parts on both board sides. This saves space and allows tricky setups. It proves very handy in PCBA manufacturing for devices with many uses. In those, adding sensors, processors, and connection parts needs careful placement. Our PCBA process backs this up. It works with rigid, flex, and rigid-flex PCBs. Thus, even detailed designs come to life with little fixing needed.

Improved Reliability and Performance

SMT parts are tinier and not as heavy. This lowers the chance of stress from mechanics and shakes. Shorter leads cut down on extra inductance and capacitance. As such, signals stay clearer. Devices run at higher speeds too. For uses needing strong reliability, like medical gear or electronics, this means better results. In our PCBA manufacture, we use strict checks with PCBA test fixtures. They confirm solder connections and part work. We reach a pass rate over 99.5%.

Increased Automation

Automatic systems form the core of SMT's strong points. PCBA machines take over tasks like printing solder paste, placing parts, and reflow soldering. They sharply reduce worker costs and mistakes by people. For one, automated optical inspection (AOI) and X-ray tools spot flaws right away. This keeps quality steady. Such automatic work in the PCBA process supports growth in output. It goes from test models to big batches. And it does so without losing accuracy.

Increased Density – More Components in a Smaller Space

SMT allows more parts per area. It fits extra features into small boards. This matters a lot for tiny electronics. There, room is tight. With tinier packs like QFN and BGA, designers fit up to 50% more parts per square inch. This beats through-hole ways. In our PCBA manufacturing, we deal with boards that have trace/spacing as narrow as 2.5mil. We back high-density interconnect (HDI) tech too.

Ability to Co-Exist with Through-Hole Components

SMT does not stand alone. It works alongside through-hole parts in mixed setups. This combined method helps in cases needing strong power parts. Those gain from TH's solid build. Our PCBA process has selective soldering for these mixes. It offers options without losing speed.

Smaller, Lighter Boards – Great for Today’s Electronics

SMT's small size leads to boards that weigh less and are slimmer. They fit portable items perfectly. Lower weight cuts shipping fees. It also improves how users feel about products like drones or IoT devices. In PCBA manufacture, this cuts material use. That helps the environment.

Reduced Need for Hole Drilling or Manual Intervention

SMT skips most drilling. So, it shortens making time and expenses. Automated PCBA machines manage putting parts in place. They cut hand adjustments. This quickens the PCBA process. You see this in our fast services. There, test models assemble in just 8 hours.

Ease of Assembly

SMT makes putting together easier with set steps. Parts are handled simply. Reflow soldering gives even connections. Our plants pick no-clean flux and lead-free ways. These meet RoHS rules for world markets.

SMT for Printed Circuit Board Assembly

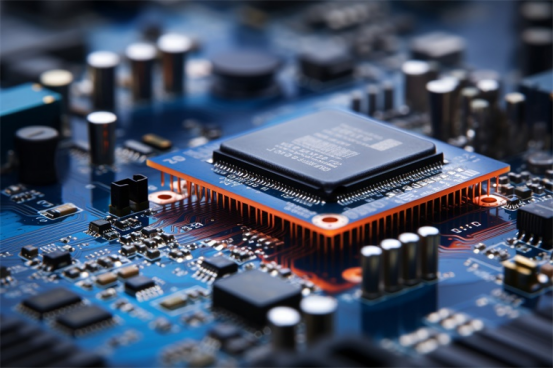

In printed circuit board assembly, SMT leads the way. It matches current making demands. At our Shenzhen plant, we blend SMT into a wide PCBA process. This covers PCB making, getting parts, and last checks. Our top gear includes auto solder-paste printers with solder paste inspection (SPI). It also has multi-zone reflow ovens. These give exact control over soldering heat.

Quality matters most in PCBA manufacturing. We do full checks with AOI for outer flaws. X-ray finds hidden gaps in BGA solder balls. PCBA test fixtures help with ICT for electrical flow. Functional testing copies real use. It makes sure things work. This careful method cuts errors. Our issue rate stays under 0.2%.

SMT aids quick model making too. This is key for repeated designs in fields like telecom and consumer gadgets. Our no-MOQ rule and fast web quotes open it up for new companies and big firms. We manage all inside. From plain PCB making to full box assembly. So, we watch quality and times. This gives ready-to-use fixes smoothly.

Adding SMT to your PCBA plan raises output. It also guards your designs from coming tech shifts.

Frequently Asked Questions

What is the difference between SMT and through-hole in PCBA manufacturing?

SMT mounts components on the surface without holes, allowing for denser, automated assembly, while through-hole uses leads inserted through the board for stronger mechanical bonds but slower production.

How does SMT improve the PCBA process?

SMT enhances efficiency through automation with PCBA machines, reduces board size, and increases component density, leading to faster production and lower costs.

What role do PCBA test fixtures play in SMT assembly?

PCBA test fixtures are used in ICT and FCT to ensure electrical integrity and functionality, detecting issues like shorts or opens post-soldering.

Can SMT be used for high-volume PCBA manufacture?

Yes, SMT is ideal for high-volume production due to its automation, scalability, and compatibility with advanced PCBA machines.

What industries benefit most from SMT in PCBA manufacturing?

Industries like medical, telecommunications, and consumer electronics benefit from SMT’s compact designs and reliable performance.

Ready to Elevate Your PCBA Project?

As a top maker, provider, and plant focused on PCBA manufacturing, we at PCBA Store promise full solutions fit to your business wants. If you grow output or make test designs, our skill in SMT and wide services gives quality, quickness, and low costs. Reach us now for a fast quote. Feel the gain of teaming with a solid PCBA pro. Check our site or email to start your next job.