General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

What Are Flexible Printed Circuits (FPC)?

joey / 2021-01-09

Contents [hide]

What Are Flexible Printed Circuits?

Simply put, flexible printed circuits are circuit boards that have the ability to bend or twist. From this assertion, it is obvious that they are distinguished by a flexible construction. That is why electronic engineers and designers use them in applications that demand for their qualities. They are also referred to as flex circuits and are mostly used in small electronic applications. Since they are characterized by their ability to bend, flexible printed circuits are made of flexible substrate such as polyimide. Another important quality of flexible printed circuits is that they have superior heat dissipation than printed circuit boards. It is this quality that makes it possible for the electronics that use it to stay in quality condition for a long time.

The Differences of Flexible Printed Circuits and Standard Printed Circuits Board

There are several differences between Flexible Printed Circuits and Standard Printed Circuits Board. It's important to point out that though both of them have a similar electrical function, they have notable structural and mechanicals variations. The first difference between the two is that a Flexible Printed Circuit has the ability to bend and twist while the Printed Circuit Board cannot. This particular difference deems it necessary for the two to have different manufacturing materials, processes, and designs. From the above assertion, let's look at the different materials that Flexible Printed Circuits and the standard Printed Circuits Board use in their applications.

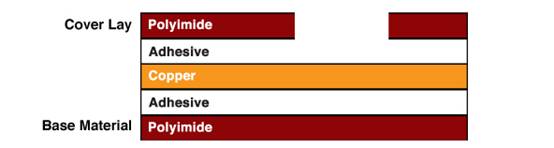

For the base layer, it has to be rigid and usually reinforced by glass for a printed circuit board. In this case, the most common material used to make it is FR4. The material used provides the much-needed stability, contains thermal resistance, and has excellent mechanical force. However, it doesn't have the capacity to bend. On the other hand, for the flexible circuit, the base materials used are mostly made of polyimide. The advantage of using this material is that it has excellent flexibility abilities, but it is limited on its capacity to provide mechanical support. Additionally, its dimensional stability is limited.

In respect to adhesives, the requirements for printed circuit boards are majorly inclined towards thermal and chemical qualities. The main reason behind this is that they don't flex. This is not the same for a flexible printed circuit. Since it has to bend, the adhesive used has to allow bending for the application to work effectively. There has to be some considerable amount of stretching for an adhesive that's meant for a flexible circuit. The bottom-line here is that an adhesive that's fit for a flexible printed circuit contains different thermal, mechanical, and chemical qualities from that of a printed circuit board.

Lastly, we'll look at the copper film. Essentially, there are two kinds of copper film. The first one is the Electro Deposited and the other one is the Rolled Annealed. Between the two, Rolled Annealed has more flexible qualities and, thus it's the best option for a flexible printed circuit application. On the other hand, though Electro Deposited copper has a bit of flexibility, it is majorly used for the production of printed circuit boards. The choice of copper carries a great deal of significance for the performance of a flexible circuit.

It is quite obvious, based on the above differences, that the design specifications for a flexible printed circuit and a printed circuit board have significant variations. For this reason, it's imperative for designers and engineers to be aware of the differences between the two so as to avoid failures.

Types of Flex Circuit Boards

There are various flex circuit boards. Normally, they are designed according to diverse configurations and specifications. It's worth pointing out that they are also categorized based on layers. Let's get to understand the different types of flex circuit boards based on configurations and on layers.

Flexible Circuit Boards Classification Based on Configurations

HDI Flexible Circuit Boards

These circuit boards are characterized by high density interconnect. If you are looking for printed circuit boards that have a higher performance, these are the ones to opt for. Basically, they produce a superior level of performance compared to the normal flexible circuit boards. The reason why they have a higher level of performance is that they incorporate various features and that they have advanced designs and construction. Additionally, HDI flexible printed circuit boards use thinner substrates compared to the normal ones. This goes a long way to improve their performance as well as decrease their sizes.

Rigid-Flex PCBs

Just like the name suggests, these particular circuit boards are a combination of flex and rigid printed circuit boards. Generally, a rigid-flex circuit board configuration contains a series of rigid circuits joined together by flex circuits. The advantage of the hybrid circuits is that they give designers the opportunity to enhance the ability of circuits. It's important to highlight that the rigid areas come in handy in the mounting of several components including connectors and chassis. On the other hand, the flexible areas are used to ensure resistance that is vibration free.

Flexible Circuit Boards Classification Based on Layers

Single-Sided Flexible Circuit Boards

This is among the basic types of flexible circuit boards based on layers. It contains a single layer of polyimide film. It also has a slim layer of copper.

Single-Sided Flexible Circuit Boards with Dual Access

Just like the name suggests, these circuit boards are single-sided but have the copper sheet accessible from both sides.

Double-Sided Flexible Circuit Boards

These particular circuit boards contain a double layer of conductors on either side of the polyimide layer.

Multi-Layered Flexible Circuits

This circuit contains a combination of double-sided and one-sided flexible circuits.

Based on the afore-mentioned types of flexible circuit boards, it is evident that designers and engineers have a wider spectrum of selection for different applications. It is this flexibility that makes flexible circuit boards highly beneficial.

Benefits of Flexible Printed Circuits

Capacity for design freedom

Flexible printed circuits have design freedom. They are not just limited to double layers. This is a great advantage for engineers. With this kind of freedom engineers are able to come up with complex configurations with different interconnections. In addition, flexible printed circuits are able to accommodate different components. If you ask any engineer or designer out there, they will tell you that the capacity to have design freedom goes a long way to give them the ability to exercise diversity and creativity.

They allow for high density configurations

Since they can allow for the combination of the plated through-hole and surface mounted components, they are able to give room for high density devices. The possibility of narrow separation between the components allows for the designing of lighter conductors. Through this, it is possible to provide space for additional components.

Accuracy of designs

Since flexible printed circuits are mostly designed using automated machinery, the margin of error in designs is less. This is a major characteristic of superior electronic devices. Most of the advanced electronic devices in use today use flexible circuit boards because of the high level of precision expected of them. Examples of the devices that require a high level of precision include those used in medical settings.

They are lightweight

The circuit boards can be folded easily, thus they can be positioned in compartments where other components find it hard to fit. Engineers take advantage of these circuits being lightweight to reduce package size.

Flexibility

Due to their ability to be flexible, they are able to relieve users of the stress of weight and space that rigid circuit boards often generate. It is possible to bend flexible circuit boards to various levels when installing them. This makes it possible to enhance the functionality levels of various electronics.

Long-term performance

The superior qualities of flexible circuit boards allow them to have durability and long-term performance. The characteristics of low ductility and mass contained in these boards allow them to overcome the influence of vibrations, therefore giving them the capacity to have improved performance. The ability of electronics to remain durable for a long time is a massive advantage for users. As you well know, electronics are common in households today, thus their ability to stay in good shape for a long time is an added value.

Cost reduction

The capacity of any device or material to reduce PCB cost compared to another gives it an added advantage. Given that flexible printed circuits have the ability to fit into a small space, they significantly reduce the cost of flexible printed circuit assembly. In the same vein, they reduce reworking time, testing time, and rejects, which translates to cost saving.

Viable for high temperature usage

The polyimide material in these circuit boards has the capacity to withstand high temperatures and also be resistant to materials like acids and oils. Flexible circuit boards can withstand temperatures as high as 400 degrees centigrade, which makes them a reliable option for high temperature applications.

Error reduction during flexible printed circuit assembly

The fact that they have accurate designs and have their production automated means that the chances of error during assembly are minimal.

Quality airflow

As a result of the streamlined design of flexible circuit boards, they make the running of cooling air through an electronic application possible.

Enhanced system reliability

Designers realized that circuit failures happened at the point of interconnection. For this reason, flexible circuits are designed to ensure that interconnections are minimal in order to increase the dependability of a circuit.

Ability to support various connectors and components

Designers and engineers acknowledge that flexible circuits are advantageous because they are able to accommodate an increased range of connectors and components.

Heat dissipation

As a result of the compact designs of the circuit board, there are shorter thermal paths generated. Consequently, the dissipation of heat is faster compared to that of a rigid circuit. Moreover, flexible circuits dissipate heat from either of the sides.

Materials Used In Flexible Printed Circuits

There are various materials that are used in flexible printed circuits. One of the main materials used is copper. This is used as a conductor material when making flexible printed circuits. There are other conductors that are used including: aluminum, constantan, and silver ink. Polyimide is also another material that these particular circuits use. It is these materials that make flexible printed circuits distinct from standard printed circuits boards.

Applications of Flexible Printed Circuits

Flexible printed circuits can be used for various applications. For example, they can be used for static applications and dynamic flexing. For the case of static applications, the design of the circuit board is for minimal flexing. It is during the installation that the circuit is flexed. For dynamic flexing, the circuit boards are for regular flexing. Here are a number of the applications of these circuit boards: robots, printers, and cell phones. It is also essential to point out that flexible circuit boards are largely used in applications that require high precision and regular flexing. Examples of these applications include: cameras, satellites, fuel pumps, antilock brakes, avionics, motion systems, medical devices, airbag systems, and manufacturing devices.

FPC Production Process

Single-Sided FPC:

Prepare Base Material -(Drilling material)-Pattern Transfer-Developing Etching Stripping -AOI-Surface Treatment-Cutting -Coverlay Laminate-Hole Punching -Surface Treatment-Plating Sn/PB-Legend Screen Print-ET-Profile Punching-QC-QA-Packing

Double-sided FPC:

Prepare Base Material -Drilling -PTH-Surface Treatment-Pattern Transfer-Developing Etching Stripping -AOI-Surface Treatment -Coverlay Laminate-Hole Punching -Surface Treatment-Plating Sn/PB(NI/AU) -Legend Screen Print-ET-Profile Punching-QC-QA-Packing

Conclusion

Circuit boards have a significant role to play in the functioning of electronics. Essentially, they are used to make the operation of electronics possible. Conductive pathways and electronic components make electronics run. Flexible circuit boards are present in many electronics including smartphones, tablets, smart watches, calculators and many more. The pivotal thing to note is that circuit boards are different and, thus, are used for different applications. Specifically, a flexible printed circuit and a printed circuits board have different characteristics and applications. It is these differences that designers should be aware of in order to avoid system failures. One of the major differences is that while the flexible printed circuit can bend, the printed circuit board cannot bend. A critical look at both circuits reveals that there are both mechanical and structural differences that engineers exploit when using them in electronics. From the discussion above about flexible printed circuits, it is evident that these circuits are diverse and have multiple benefits in their applications.

As the premier expert in flexible circuit fabrication, PCBASTORE brings a unique combination of technology and quality that offers a competitive supply of flex circuits and rigid-flex circuits and other flexible circuit products.

To find out more, you can be reached at www.pcbastore.com or email us at: sales07@pcbastore.com

Previous article:PCB Manufacture Comparison