General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

How to Reduce PCB Prototype Price?

Aries / 2021-03-03

Contents [hide]

What Is PCB Prototype?

A PCB prototype is a sample of a product. The purpose is to test the effectiveness of the final product design. In most cases, PCB prototypes test the basic functionality of PCB board designs. Different types of PCB prototypes are available to test different aspects of board designs. While working on a project, engineers use PCB prototypes to test various stages of their design. Some PCB prototype examples are visual models, working prototypes, proof-of-concept prototypes, and functional prototypes.

When the visual model will offer an idea about the physical aspects of the shape and structure, the proof-of-concept prototypes will focus on the imitation of the primary functions of the product without knowing the capabilities of the final product. The working prototype will contain all the features and functions of the final product. It will help engineers to identify the potential problems in designs. The functional prototype will help you with the most accurate idea. The engineers can use it for the final design.

Why Use PCB Prototype?

A PCB prototype can help engineers to find out the potential design flaws. Once they get the idea, they can make improvements in the design accordingly. It will save a lot of time and money as well. In addition to the above, users can expect the best possible design.

While creating a PCB-based design, engineers need to go through many design processes. A PCB prototype will enable them to test a new design quickly and finish the project fast. Different types of PCB prototypes can help them to test the design before using it for full production. It will minimize waste and maximize investment. It will influence the end cost.

Engineers can find design flaws and imperfections. They can fix any issue at an early stage. That is going to save a lot in the end. However, you cannot find out flaws fast without a PCB prototype. If you find any flaws at the later phase, you are going to spend much more to correct the design. Also, they can use PCB prototypes to test the single function of any complex product.

A PCB prototype will offer an accurate picture of the PCB design and how it will work in the end. The engineers will have a complete picture of the design. The objective is to find out potential problems and make improvements to develop a better product. In brief, PCB prototypes will contribute to the overall success of the product.

How Long Does It Take to Make A PCB Prototype?

We cannot give the exact time because all the boards are not the same. When some of them might take a few weeks, others might take months. We can take the example of the middle-range PCB prototype and a run-of-the-mill PCB prototype. They will take only a few weeks.

Supply chain interruptions are another determining factor. They might delay a project even if the design is completed. The lead time of some components might alter the time significantly. In that condition, you can work with electronic contract manufacturers to get some alternative components. It will enable you to complete your project fast.

What Is the PCB Prototyping Process

You will have to understand your prototype needs, and then you can start the process. You will have to go through the following steps to design the final product.

Design: Use an advanced software suite for the design

Schematic design: It will offer crucial information about components and materials. Engineers can use the information to find out potential issues.

Bill of materials: In this step, you will have to prepare the list of materials. It will include quantity, value, footprint, manufacturer part number, and reference designators.

Routing design: The process will design the routing. Many factors will influence the routing that includes signal noise generation, power levels, and noise sensitivity.

Checks & creating the photo film: You need to check the design thoroughly, and then you can create a photo film.

Printing & aligning, and fusing inner layers.

Drilling the holes

Copper plating: The process will give a chemical bath to deposit a copper layer

Outer layer imaging & copper and tin plating

Final itching: It will remove excess copper

Apply the solder mask & then apply the surface finish

Apply silkscreen and cut the board from the larger panel

Sourcing: For the assembly stage, you will have to source all the components

Assembly: During the assembling process, the required components will be attached to the board

Solder Paste Stenciling

Use pick and place machine

Reflow soldering

After following all these steps, you will have to inspect for the connection quality and functionality. A few boards might require other components. You will have to take this factor into your consideration. In the end, you will have to conduct a functionality test.

What Does PCB Prototype Cost Include?

The PCB prototype cost will include a lot of things. Several factors will contribute to the end cost. The most important factors are the following.

Material: Some laminate and substrate PCB materials are a bit expensive than other materials. For high performance, you will have to spend more.

Board Size: You are going to spend more on larger boards. If it is small, you will have to spend less.

Speed: The end cost will be more if you want printed circuit board rapid prototyping.

Complexity: Complex wiring, very dense boards, and high volume components will increase the end cost.

These are a few factors that will decide the cost of PCB prototyping. A PCB prototype can cost you a few dollars or a hundred dollars depending on the design, material, complexity, and size. However, you can reduce PCB prototype price. You can go for a higher production batch. The assembler is going to charge you more for a smaller batch.

How to Reduce PCB Prototype Price

Here are the 5 aspects that we can consider to reduce the PCB prototype price when we want to save money on it.

1. Optimize The Design

Optimize the PCB layout and assembly process is the smarter choice of cost down. The goal is to make the fabrication easier and use fewer and more cost-effective parts which will significantly lower the cost of each PCB. In the long run, this will enable your company to reduce costs and deliver high quality PCB.

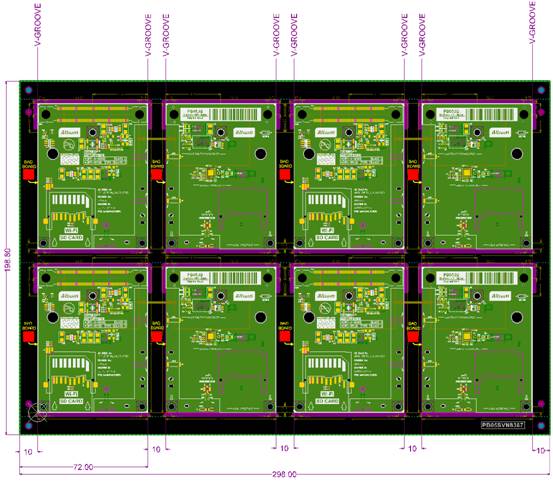

2. Panelized PCB Prototype

Pacing multiple PCBs on the same panel allows them to be processed at the same time, it really to do good for assembly.

The more PCBs on one panel, the more cost effective it becomes.

3. Get Support From Manufactures

Get the PCB prototype supplier involved and listen to them during the design process. Some engineering problem, such as board stack up, clearance issues, material or vias, and the other special requirements, these could cause problems in the fabrication.

By communicating and agreeing with in advance, this would give the manufacturer plenty of time to resolve any issues or offer an alternative solution.

Of course, you have enough time to choose another PCB manufacturer if they cannot meet the demands.

4. Choose A Professional Manufacturer For PCB Prototype

PCB prototype essentially is not a mature product, there may be some small errors need to be modified. The professional PCB supplier has the ability to review the design and resolve any potential problems. Even the skilled line workers have the possibility to propose a way to optimize assembly. Their manufacturing expertise is a great help to shorten the delivery of PCB prototype.

5. Pay Attention To Component Procurement

When you choose the component for the boards, be sure to consider its specificity. some components will request big MOQ order, which is not good for small PCB prototype orders. The purchasing team should help customers find alternative parts with better price. They will sources components from the most reputable suppliers in the industry to reduce procurement time.

Conclusion

A PCB prototype can be helpful to get an exact idea about the end product. PCB prototypes are available to support different phases of the design. A PCB prototype can reduce the end cost and timeline of the project. They can test the components individually. Engineers can use these prototypes to spot potential issues and improve them immediately without affecting the end product.

It is wise for electronic manufacturers and businesses to first order a PCB prototype sample, the purpose of doing so is to go through testing in order to detect any potential errors and optimize for the final stage.

The engineers who are in charge of this project, of course, take into consideration of reducing PCB prototype price.

Let's discuss the ways to make the PCB prototype more cost-effective.

The team of PCBA Store does not only pay great attention to the process of PCB prototype but also move from prototype to production more effectively.

We are ready to support you on reducing PCB cost. Contact us freely to make pcb prototype an easy part of your project.

Previous article:What should your multilayer PCB consider in the 5G era?